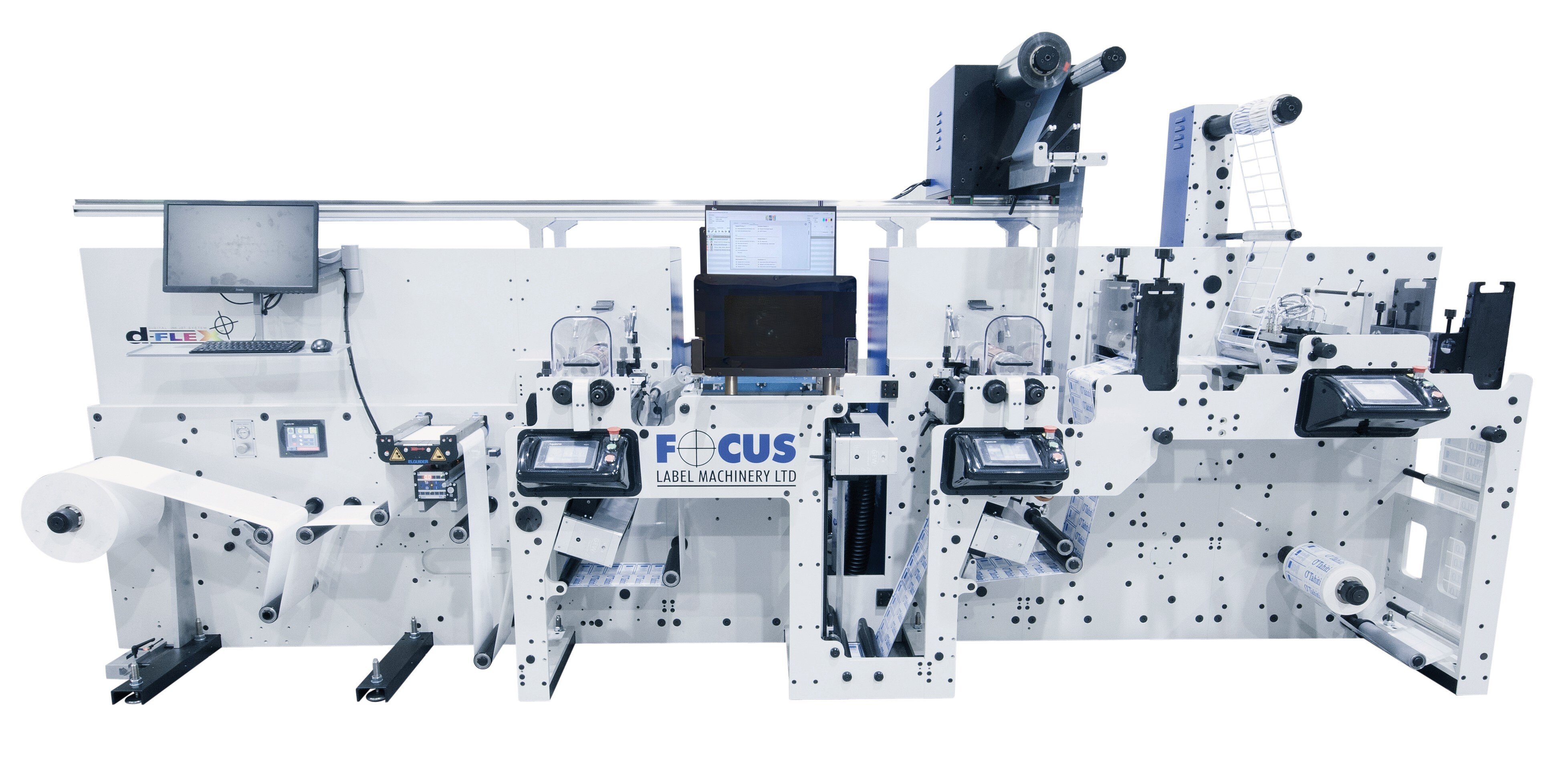

Vista Labels installs second Reflex 330 from Focus Label Machinery

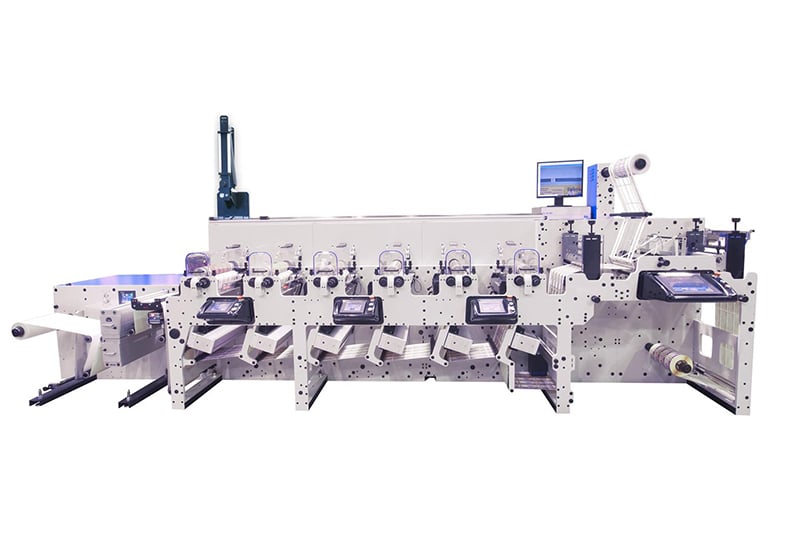

Linney Invests in Focus Proflex 330SE Hybrid press

Linney, based in Mansfield, is one of the UK’s largest independently owned print & packaging companies, encompassing a wide range of marketing and communication services, alongside large-scale print, warehousing and fulfilment facilities.

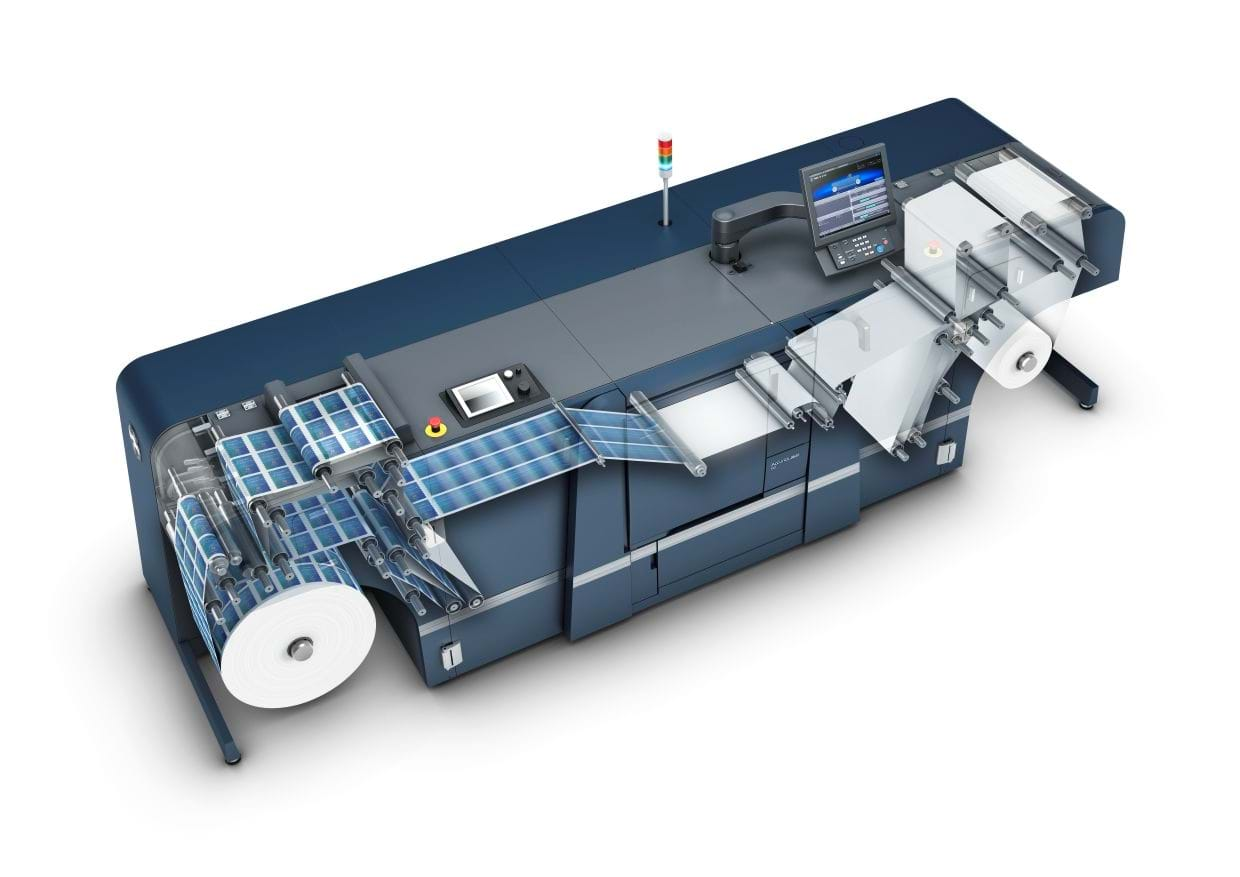

LabFax invests in Konica Minolta Accurio Label 230 digital press

Shropshire-based converter LabFax has become the latest UK label printer to install the Konica Minolta AccurioLabel 230 digital toner press.

Simply Inkjet and Focus Label Machinery Ltd Announce Strategic Partnership

How On-Demand Printing Is Changing the Printing Industry, And How You Can Respond

Despite the pandemic & subsequent supply chain earthquake in many industries, research indicates that the digital printing market is successfully weathering the storm, with an Allied Market Research report predicting growth in excess of 200% by 2027. Three key factors are playing their part in securing the textile print industry’s future:

Why Are Shorter Flexographic Print Runs Increasing In Demand?

We all know that the Covid-19 pandemic has changed virtually every aspect of the economy, and the printing industry is no exception. The shift towards shorter and more agile print runs started several years before the pandemic, but being in lockdown has accelerated this trend. There are a few reasons why this trend is continuing to grow, ranging from advancements in technology and changing consumer demands to increased concerns about sustainability.