Neglecting to clean high-speed printing machines can lead to the accumulation of dirt and debris which significantly affects print quality and may cause mechanical failures that are expensive and disruptive to resolve.

Exploring The Benefits Of Ultrasonic Anilox Roll Cleaning For Your Business

Anilox Rolls Performance: What Why and How?

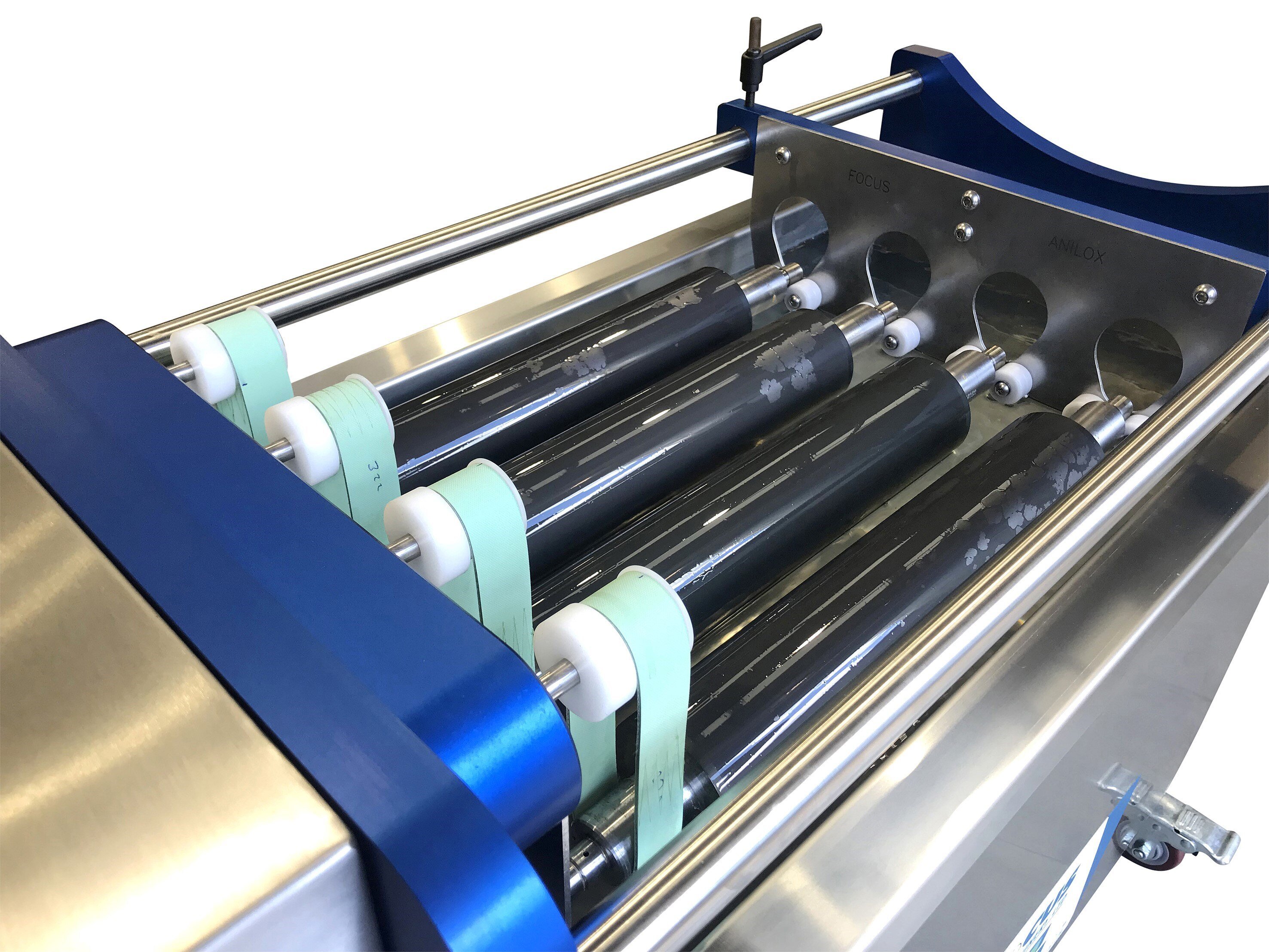

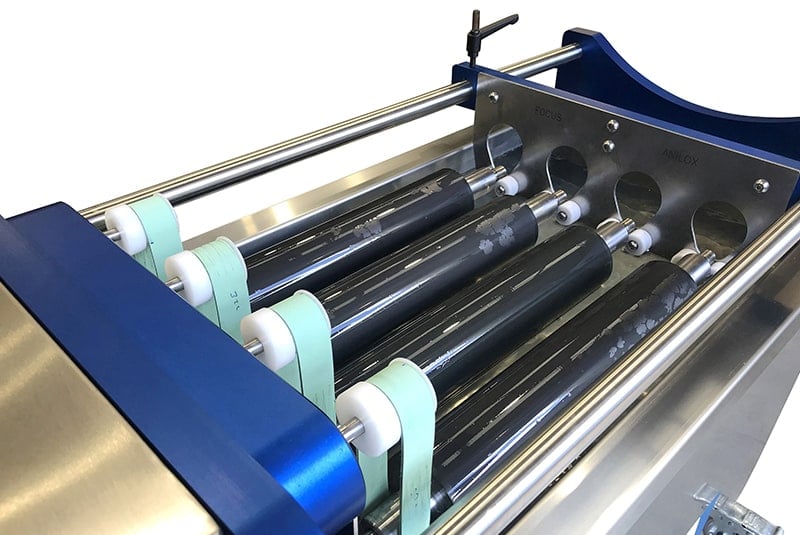

A key part of any Flexographic press is the Anilox Roll, its sole purpose to to carry a controlled volume of ink to the printing plate for consistent ink transfer onto the substrate. A number of things can affect your Anilox rolls performance.

3 Advantages of Ultrasonic Cleaning for Anilox Rolls on Printing Machines

Over time, printing machines in high-speed, high-volume production lines accumulate dirt and other contaminants, which can affect the quality of their output and cause mechanical failure. Cleaning the machines can, understandably, seem onerous, especially if you feel that valuable production time is being wasted while the task is carried out: after all, surely it’s more profitable to have your production line operating at its maximum capacity?

Anilox Scoring- What, Why, and How?

Anilox scoring seems to be a never-ending challenge: it can occur immediately at start of a new production run, other times it can appear suddenly, and other times it comes and goes. Yet it never seems to totally go away.

Choosing The Right Anilox For Each Label Printing Application

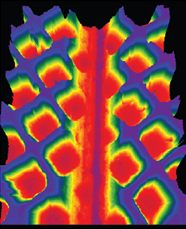

In today's highly competitive environment an ever increasing creativity in labels & packaging design innovations is paramount. The flexographic print process has enjoyed a period of continual development, elevating its reproduction capabilities far beyond what has traditionally been possible, and putting it in the same perceived level of gravure and offset printing. This has been possible thanks to the recent advancements in Press design, Printing Plate and ink technology. Anilox Roll technology has had to adapt to these advances itself and flexo Printers can challenge both Offset & Gravure quality. It is vital that printers not only understand their Anilox screen specifications, i.e., line count and volume but they must also understand their Anilox engraving type and cell geometry to maximize Anilox efficiencies. Line count provides definition and cell volume colour strength and density; however the cell shape and engraving geometry is crucial to maximize the Anilox ink-transfer properties.

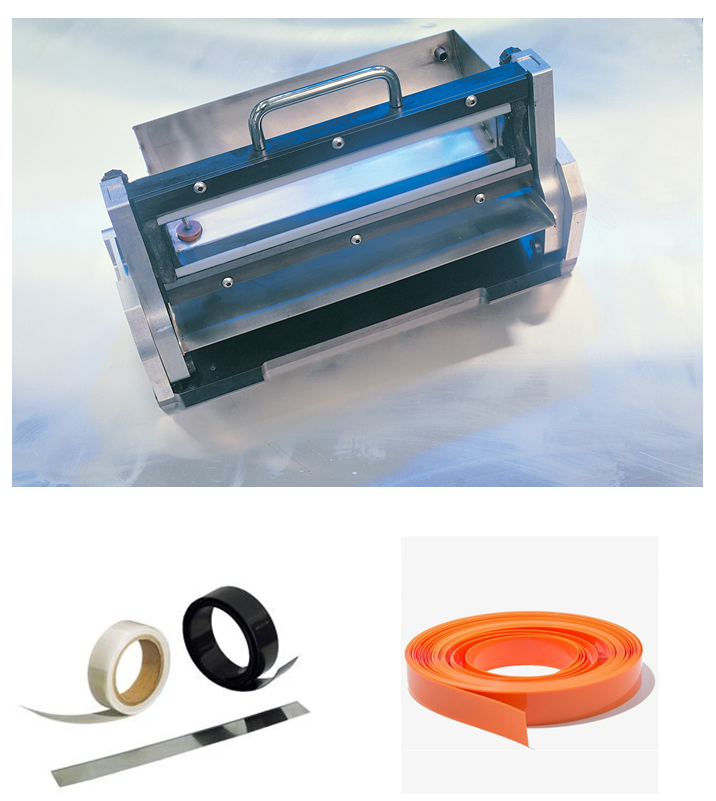

Anilox Roll Scoring in Printing - What, Why & How

Anilox scoring seems to be a never-ending challenge: It can occur immediately at the start of a new production run, other times it can appear suddenly and other times it comes and goes. Yet it never seems to totally go away. In This Article We Will Cover The Following: What is anilox scoring? Why does anilox scoring occur? Doctor Blade Selection Steel v Synthetic v Composite How to minimize anilox scoring. Regardless of the level of pressroom knowledge, anilox scoring can rear its head and if left unchecked it can become very expensive. Firstly in replacing the anilox and then the time and material cost because of the spoiled production.