Neglecting to clean high-speed printing machines can lead to the accumulation of dirt and debris which significantly affects print quality and may cause mechanical failures that are expensive and disruptive to resolve.

Exploring The Benefits Of Ultrasonic Anilox Roll Cleaning For Your Business

Anilox Rolls Performance: What Why and How?

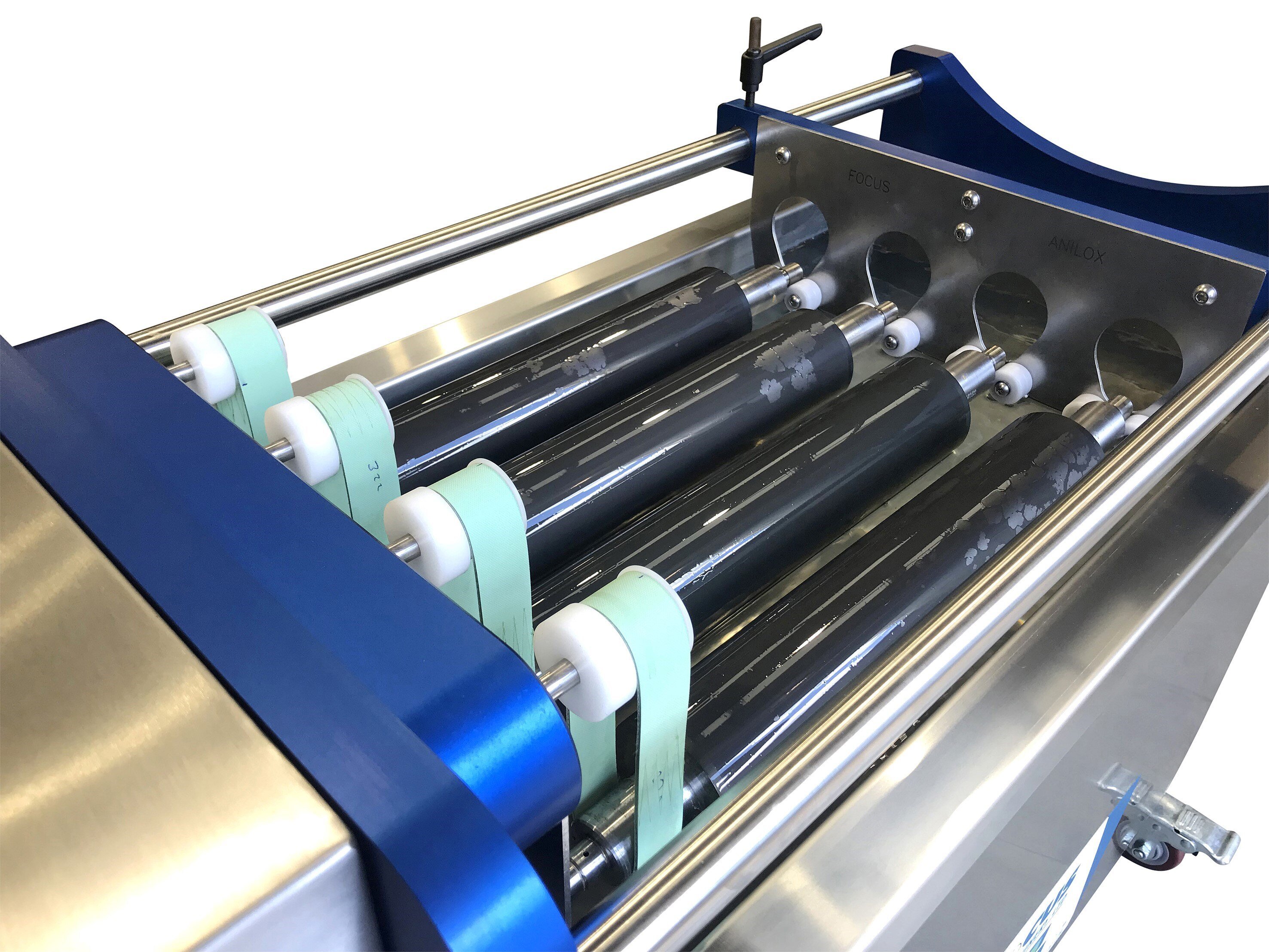

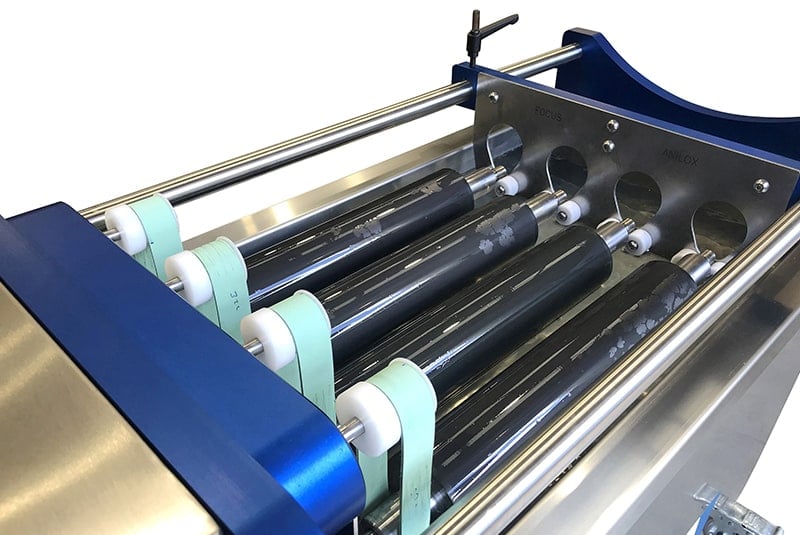

A key part of any Flexographic press is the Anilox Roll, its sole purpose to to carry a controlled volume of ink to the printing plate for consistent ink transfer onto the substrate. A number of things can affect your Anilox rolls performance.

3 Advantages of Ultrasonic Cleaning for Anilox Rolls on Printing Machines

Over time, printing machines in high-speed, high-volume production lines accumulate dirt and other contaminants, which can affect the quality of their output and cause mechanical failure. Cleaning the machines can, understandably, seem onerous, especially if you feel that valuable production time is being wasted while the task is carried out: after all, surely it’s more profitable to have your production line operating at its maximum capacity?

Anilox Roll Technology For Printing Garment Labels, Textile Ribbons & Elastics

A key element in Letterflex technology & directly printing textiles is the anilox roll. In order to achieve the best print quality possible the anilox roll should transfer the minimum volume of Ink to the printing plate to achieve the desired coverage. Factors that need to be considered are the type of image, substrate & ink types. All of these will affect the specification of the anilox roll that needs to be selected for the optimum result.