With concern growing about the fragile state of the world’s environment, businesses in all sectors are under pressure to adopt eco-friendly practices in the drive to attain Net Zero. Narrow web printers are widely used in label and packaging production by many companies but their impact on the environment can be significant. However, by implementing some cost-effective environmentally friendly strategies, businesses can reduce their carbon footprint and save money.

Implementing Green Skills in Your Company With Narrow Web Printers

Flexible Packaging Substrates For Narrow Web Applications

Flexible packaging is often chosen over traditional packaging materials because it offers increased versatility, durability, and sustainability, without compromising on the quality of the print. This has been the long-time preserve of wide web converters for large volumes.

4 of The Best Narrow Web Printing Machines Out There Right Now!

Today’s Printing industry demands machinery that can print economically small & large volume orders, maintaining the highest print quality with as little waste as possible and the higher the output and faster the production, the better. However one printing line does not suit all requirements, often equipment has to be tailored to individual needs or specific requirements. Some of today’s best printing lines combine all of the above as well as offering a number of innovative features to help printers achieve their individual production goals.

4 Of The Most Popular Products To Print With A Narrow Web Flexo Printing System

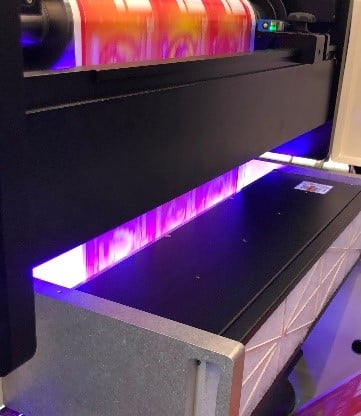

Narrow web flexo printing is a cost-effective and reliable solution for mid-large volume print runs. Operating with webs that, typically, are between 10” and 16” wide, narrow web flexo printing works well with UV-curable inks which dry quickly, thereby eliminating the need for additional drying equipment, and delivering a lower ink cost per square metre without compromising on image quality.

How To Reduce Downtime With A Narrow Web Printing Machine

Today’s narrow web printing machines are at the centre of the printing industry, offering many options for customisation. There are many ways to reduce downtime with these machines, by using the right technology, the right consumables, and by optimising your print process.