The textile label printing industry is already experiencing rapid change, and these advances are unlikely to slow down in the next few years. As consumer preferences evolve and demand for sustainable printing solutions rises, label printing businesses need to be at the sharp end to adapt to new trends and remain agile in a market that is continuously changing.

The Future of Apparels & Textile Printing: Trends and Predictions 2025-2030

Branding – Textiles & Garments, Labels & Printed Ribbons/Elastics: What are the best print technologies to use for different applications?

Printed fabrics are widely accepted in production of home textiles & the fashion & sports garment industry. Fashion & sports wear demand high impact decoration and graphics with a rapid turnaround for fast design, production and delivery to the high street.

Pro Tips for Maximum Success Within Textile Ribbons for Garments

Label print runs that produce poor quality or unattractive products will rarely earn your business a reputation for excellence and can significantly impact your profits, as your clients will inevitably work with other label printers in future.

ITMA 2019: What We Learned

The four-yearly ITMA textile and garment technology expo is the world’s leading event for the international textile industry, showcasing the latest in materials technology and technical innovation – including in textile printing. As such, it is a great opportunity for businesses like us to engage with suppliers, customers and friends in one place – and also to keep up to date with the changes transforming the industry.

The Current State Of Print Technology In 2017

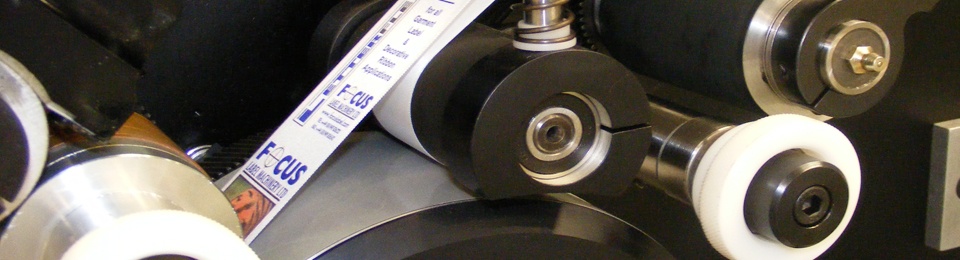

For the past 20 years the print technology sector has developed along several trajectories. First there was the growth of automated, computerised features and a decline in labour-intensive, manually operated presses. Then there is the interaction between digital and traditional flexographic technologies. A new generation of so-called hybrid presses has sought to bridge the gap between the cost effectiveness of flexographic presses for large print runs and the convenience of digital technology.

How To Maximise The Efficiency Of Your Textile Printing Machinery In Four Easy Steps

Any kind of textile processing, including the production of garment labels, relies on the continued efficiency of printing machinery. Without it, the quality of your textile printing will be inconsistent. There are many ways to maximise your machine’s efficiency. 1) Manage Humidity and Static Regardless of the type of textiles you print at your facility, humidity will play a role. Too-high humidity will negatively affect your machinery, causing damage and slowdowns in production. Adding to this, any change in the moisture content in the air can impact the textiles themselves. For example, added humidity will lessen the elasticity and tensile strength of some fabrics.