Label printing machines are evolving at a rapid rate. ‘Under the skin’, today's printing machines are a vastly different animal than what was available commercially even a decade ago, so if you are running a printing operation, now is a good time to have a look at what the latest technologies have to offer.

3 Main Reasons To Upgrade Your Label Printing Equipment

New Vs Used Label Printing Machines: Which Offers The Best Value?

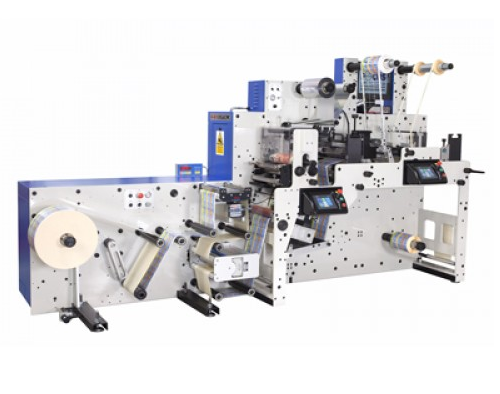

If you are in the market for a new flexographic, digital or hybrid printing machine you have many options to choose from. There are excellent quality new machines available from companies like Focus Label, and there are also many used machines that can be had at a significant discount. While the up-front cost for a new machine that is made in the UK will be higher than any used machine, investing in new equipment will offer you some distinct advantages.

How To Buy A New Label Printing Machine From Focus Labels

At Focus Label we build some of the best flexographic printing machines in the world right here in Nottingham, England. If you are wondering how buying a flexo machine from us works, we are happy to tell you more about the process. High-end flexographic printing machines are largely custom made, and this allows you to create hardware that will be purpose built for your needs. The process can be a lengthy one, so if you are in the market for a new flexo printing machine, there is no time like the present to get in touch with us.

4 Mistakes To Avoid When Buying Flexographic Printing Machinery

You may think that, once you’ve decided to purchase a flexographic press in principle, that your work is done. However, getting to the point of making a purchase decision – lengthy as this may be – is only part of the process. There are several common errors which can occur, both during and after purchase, that can make your new press more of a challenge to work with than it needs to be. This article will cover four of these commonly-made mistakes.

Why Buying A Flexo Label Printing Machine Will Be One Of The Most Significant Purchases You Will Make

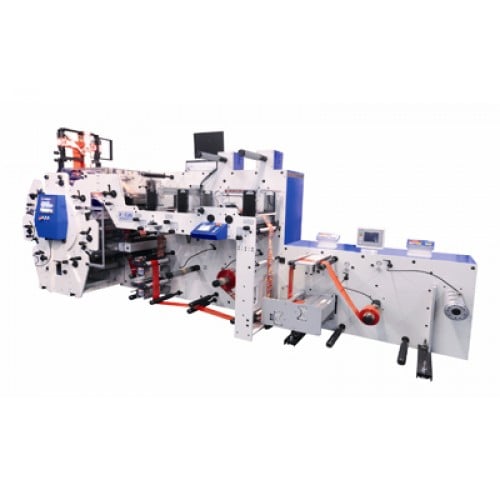

There may be many reasons why you want to invest in a new flexo printing press for your label production. The most common reason many businesses purchase a new machine is that they wish to increase their margins on production or capacity. With its high speeds, quality output and many available features, your new press will certainly accomplish that. In fact, your flexo label printing machine will affect your productivity at every level, making it one of the most significant purchases you will make, and for several reasons.

Why Flexographic Printing Equipment Is Far Better Than These Alternatives

There are several kinds of printing options available for commercial printing businesses. However, flexographic printing offers the most benefits by far. Let’s look at flexo’s benefits and then compare these to other printing types. Why Flexo Is A Superior Choice For Your Printing Needs Flexo-printing is an extremely versatile and popular method of printing. It allows any flexible material to be printed on, even those which may seem impossible to carry a print, such as cellophane, plastics and metallic films. This ability makes flexo ideal for printing on food packaging, Chemical & Pharmaceutical and product labels.