With such a wide range of options to choose from, choosing the best label printing machine for your application can be a daunting prospect, especially if you know very little about ribbon printing technology and what is on the market.

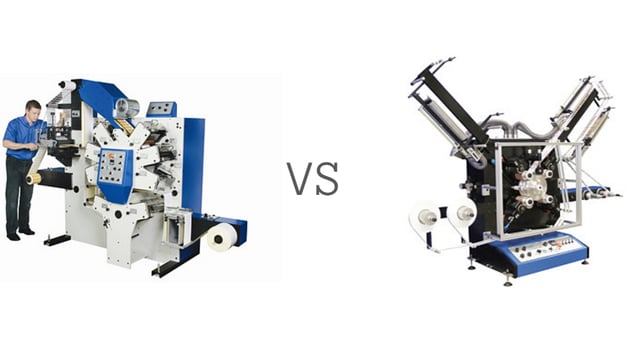

Among the many products that exist, there are two machines that are definitely worth further consideration in the ribbon printing realm: our B4 range, and the LX range.

The Letterflex B4 – Entry-Level Cost-Effectiveness

The B4 equipment range offers high production output speed as well as multi-ribbon printing. The advanced enclosed ink cartridge technology allows for near-immediate job changes and full colour to be applied to any label printing project.

Whether you wish to produce labels for printed apparel or are looking to print decorative ribbons, the B4 allows for successful production, whether in a plant or specialist printing setting. Built with high-quality engineering, the B4 offers a compact way to print labels onto ribbons with several drying system options including combination infra-red and fan drying.

The B4 also offers higher production capacity than the L-series printer it replaces. This compact and powerful B4 is ideal both for garment manufacturers who wish to produce their own labels, and companies focused on volume printing.

Benefits of the Letterflex B4

The B4 label printing machine requires very little training to operate, making it ideal for production managers or directors wanting fast implementation of new equipment with the operators, printers and machine supervisors on their team. The ability to set up and implement the B4 so easily also means very little interruption for managers when planning and prioritising jobs.

The fact that the B4 is manufactured in the same facility as our industrial printing machines means that businesses receive a machine that’s been manufactured with quality control as the main focus.

The Letterflex B4 offers both one and two ribbon printing for ultimate flexibility, and due to its high-quality and precision printing construction, results in far less waste being produced from printing.

There are many possibilities for printing with the B4. It offers four colour printing on a 1+1, 2+1 or 3+1 basis. Also, it allows for two unwinds and two rewinds at a print length range of 6 to 12”.

The LX Letterflex – a Professional Solution

This range of textile label printing machines offers a new way to print labels using specialised apparel and decorative transfers. The LX Letterflex utilises proprietary paper chemistry, ink, and printing transfer technology, which affixes an entire image to a garment without the need to sew in a label.

The equipment offers the highest level of advanced technology at a cost that comes in under budget. Ideal for use on printed textiles for adding trim and labels via heat transfer, the LX also allows for full colour to be used and changes made to jobs in seconds.

Benefits of the LX Letterflex

The patented ink cartridge system of the LX Letterflex, as well as a large variety of customisation options, offers true versatility to managers needing to print labels for a wide variety of applications. The ability to change cartridges quickly means seamless production with virtually no downtime.

Combination drying systems ensure that every job, regardless of size, is completed efficiently. Because of the high ease-of-use offered by the LX, training and specialist operator requirements are kept to a minimum.

A number of options are available with the LX, including anti-static bars, ultrasonic cutting systems, web cleaners, video inspection, UV drying and much more.

The sophisticated technology of the LX allows managers to use the machinery in the production of high-quality and complex transfers in multiple colours from roll to roll, while its small size makes it ideal for supplying to local garment manufacturers during the strategic global positioning process.

Learn Even More About Label Printing with our Informative, Free E-book

Both of the printers above make the entire label printing process more efficient, thereby reducing the associated costs of printing textile labels. When this happens, your operation becomes more productive and more profitable.

Of course, in the label printing industry, there always seems to be so much to learn. That’s why we developed a free guide, “Label Printing for Textiles”. Inside, you’ll find lots of valuable tips and advice about printing labels on several types of media, as well as how to win more work, and the best thing about it is that we are giving it away at no cost to you. Just click here to download it.