One reason for the comparatively slow growth of digital printing on textiles may be related to the extreme demands of the textile applications and the wide selection of types of textiles used in the industry. Fabric has always been inherently more difficult to print due to its flexible nature. The level of flexibility varies from warp to weft and with each degree around the bias, so guiding the fabric precisely through a digital printing press has proven to be very difficult, not forgetting the challenges of softness, fading, rub and wash resistance.

Should I Really Be Looking At Digital Print & Finishing Systems For My Business?

With increasing pressures from buyers to reduce stock levels in print & packaging and to create more innovative and attractive promotions to compete in the retail arena, the challenge on suppliers is to respond quicker and be more dynamic in the way they operate, within the supply chain & actively promote their business.

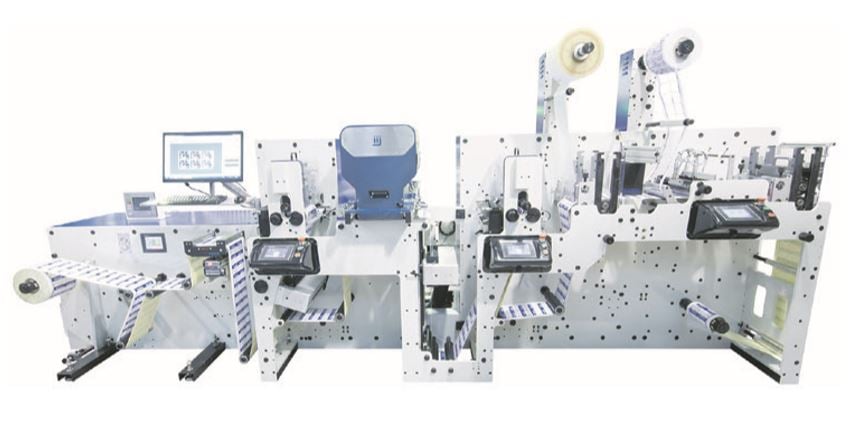

Focus Label: Custom designed label printing & finishing equipment

Packaging Company Of The Month Here at Business and Industry Today we are delighted to recommend companies that offer an astounding product and service. This is why we are pleased to present Focus Label Machinery Ltd with our Packaging Company of the Month profile.

Alternatives In Printing Textile/Garment/Apparel Labels

Historically there have been a number of chosen methods for production of printed garment / apparel labels / ribbons.

My Flexo-Press Is Faulty: Where To Look For Spare Parts?

A printing press is an important investment. It’s not a time for false economy, and nor is it a time for settling for something that’s not a perfect match for your needs. Whatever press type you have we would recommend you always purchase original parts or seek approved technical support. This might not be possible if you have imported a machine or it is an older model no longer in production or supported. At Focus Labels, we take a very pragmatic approach to a client’s relationship with their flexo-press. We’re engineers who have designed, built, and maintained our machines, and who are committed to keeping them in excellent working order.

Focus Label Are Sponsors Of The FlexoTech Awards

We are happy to announce that we are the proud sponsors of the 2018 FlexoTech International Print & Innovations Award. The FlexoTech Awards highlights the great advancements made in flexo by recognising the best work in the industry from across the world. Venue: The Royal Lancaster London , 10th October 2018