Product labels and packaging are incredibly important to maintain brand presence on the high street, but it can be difficult to decide which printing method is most suited to your customers’ needs. Digital printing machines offer an agile and cost-efficient solution to many pain points in the packaging process and are redefining the commercial landscape, as we will explain in this article.

Digital Printing: Redefining the Commercial Landscape

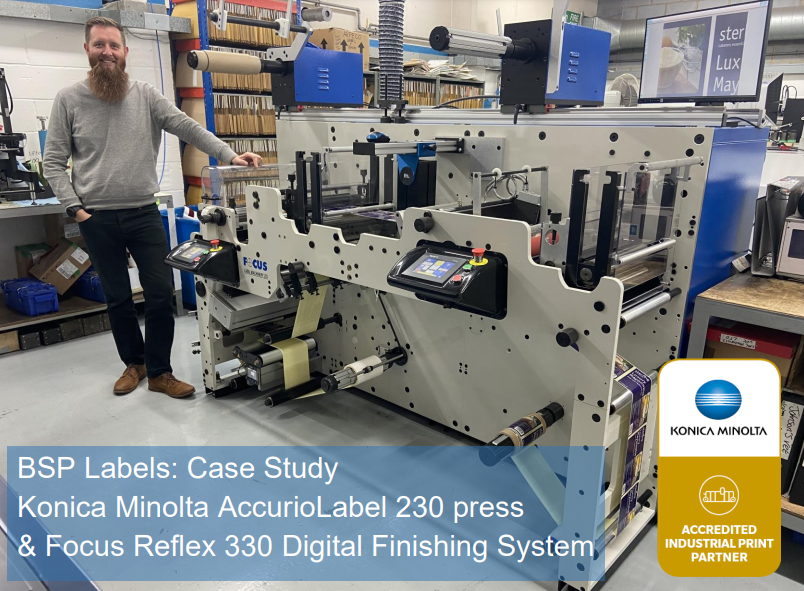

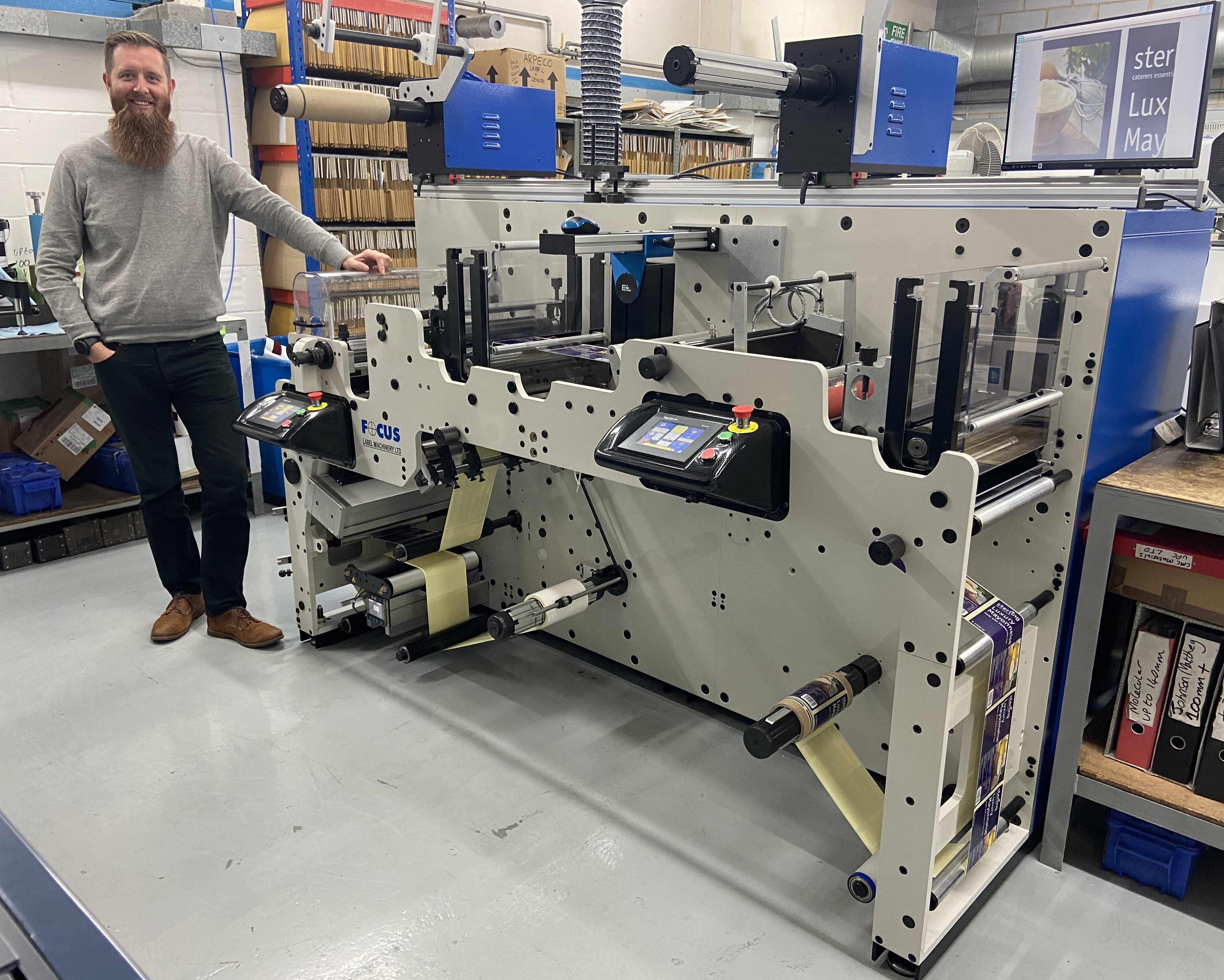

BSP Labels: Case Study Konica Minolta AccurioLabel 230 press & Focus Reflex 330 Digital Finishing System

Originally incorporated in 1968, BSP is well established as a successful UK label manufacturer and is now headed up by Martin Attaway, the son of founder - John Attaway.

Different Printing Methods That Are Used in the Production of Flexible Packaging

Flexible packaging plays a crucial role in many industries but, to meet the unique needs of various applications, different printing methods are used in its production. The choice depends on factors such as print quality, production speed, and substrate compatibility, as well as the target consumer audience and their preferences.

BSP Labels – Focus Reflex 330 Installation

Further to the recent installation of their Konica Minolta AccurioLabel 230 digital press from Focus Label Machinery, BSP Labels, of Royston, UK, has subsequently installed a Reflex 330 Digital Finishing System - again supplied by Focus Label Machinery Ltd.

Make Your Production Sustainable With Flexographic Printing

As the sixth largest producer of printing products in the world, the UK is in a prime position to enhance sustainability in the industry, and positive progress has already been made towards achieving Net Zero.

Revolutionising the Printing Industry: The Future of Digital Print & Packaging

The printing industry has undergone significant transformation in recent years, and the future of digital print promises even more innovative developments. As technology continues to advance, digital printing machines are at the forefront of an evolving industry that promises better results for more cost-efficient prices in future.