Originally incorporated in 1968, BSP is well established as a successful UK label manufacturer and is now headed up by Martin Attaway, the son of founder - John Attaway.

Based near Royston UK, the company specialises in labels for the following market sectors:

- Packaging

- Pharmaceutical

- Food & beverage

- Veterinary

- Chemical

- Automotive

‘As well as supplying our new equipment, Focus & Konica Minolta have also provided an excellent

after sales service and been on hand to give technical advice whenever needed. We have been very pleased with their products and their service.’

What were the challenges?

For many years, we were coping well with medium run & high volume jobs, using our trusty letterpress & flexo presses but didn’t really have a solution for short run label production or variable data printing. We were having to outsource to trade houses with digital presses, specialising in this type of work. The problem was not being able to control the turnaround times and not being

able to match with previously printed labels.

Why choose Focus & Konica Minolta?

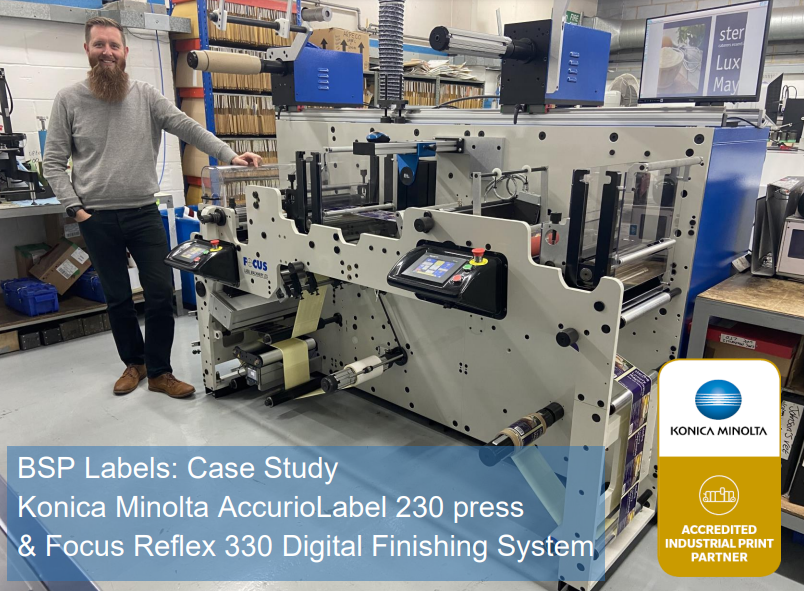

After researching digital presses for a number of years, we were invited by Focus to conduct some

print trials on the Konica Minolta AccurioLabel 230 press. Having already ruled out inkjet technology, this seemed like an interesting option for us, as the Konica press was based on dry toner technology. We already knew Focus as a supplier and were aware that they were an Accredited Industrial Print Partner of Konica Minolta, so we accepted their invitation.

The partnership between Focus and Konica Minolta was a big factor in our decision to purchase the new equipment. They worked closely together on the project from our initial enquiry though to delivery, installation & training.

We had known Focus for many years and were confident that they would look after us.

Konica Minolta equipment uses proven technology and has a large number of UK service engineers, so again – we knew that we would be in safe hands.

How did Focus help?

They helped us to trial a variety of substrates, including a few which we thought would be challenging. In the end, we were surprised to find that the AccurioLabel press was compatible with the majority of our entire substrate range.

At the same time, we were able to check on set-up times, job changes and real-time production speeds. It was also reassuring to find how easy it was to operate the press and to lay jobs out, using

the AccurioPro Flux software. In addition, Konica Minolta were on hand to demonstrate

how the software handled some tricky variable data jobs. As it turned out – they weren’t so tricky after all.

Colour management was straight forward, using the spectrophotometer which is included within the package. We were easily able to adjust colours quickly & accurately to match our pre-printed labels.

What about the finishing?

As well as digital print, we also needed to invest in digital finishing. For this, Focus demonstrated their Reflex 330 Digital Finishing System, with UV flexo station, cold foiling & converting.

The re-registration to pre-printed web was very accurate and easy to set up, using just a few

metres of material.

We also ran the Reflex 330 as a stand-alone flexo press / blank label converter at over 100 metres

per minute! This meant that we would be able to maximise the capacity of the press, even when

not using it with pre-printed stock.

We decided that the Konica AccurioLabel 230 and the Focus Reflex 330 were a perfect combination for us.

What have been the benefits?

Since installing the new equipment, we have been able to bring more work back in-house, giving us

much greater control over consistency and turnaround times. In turn, this has also led to us

winning more new orders and gaining new customers.

Going Forward:

Looking ahead, we aim to continue to modernise our production facilities and expand our portfolio,

offering a wide range of high quality labels for short, medium and long run applications.