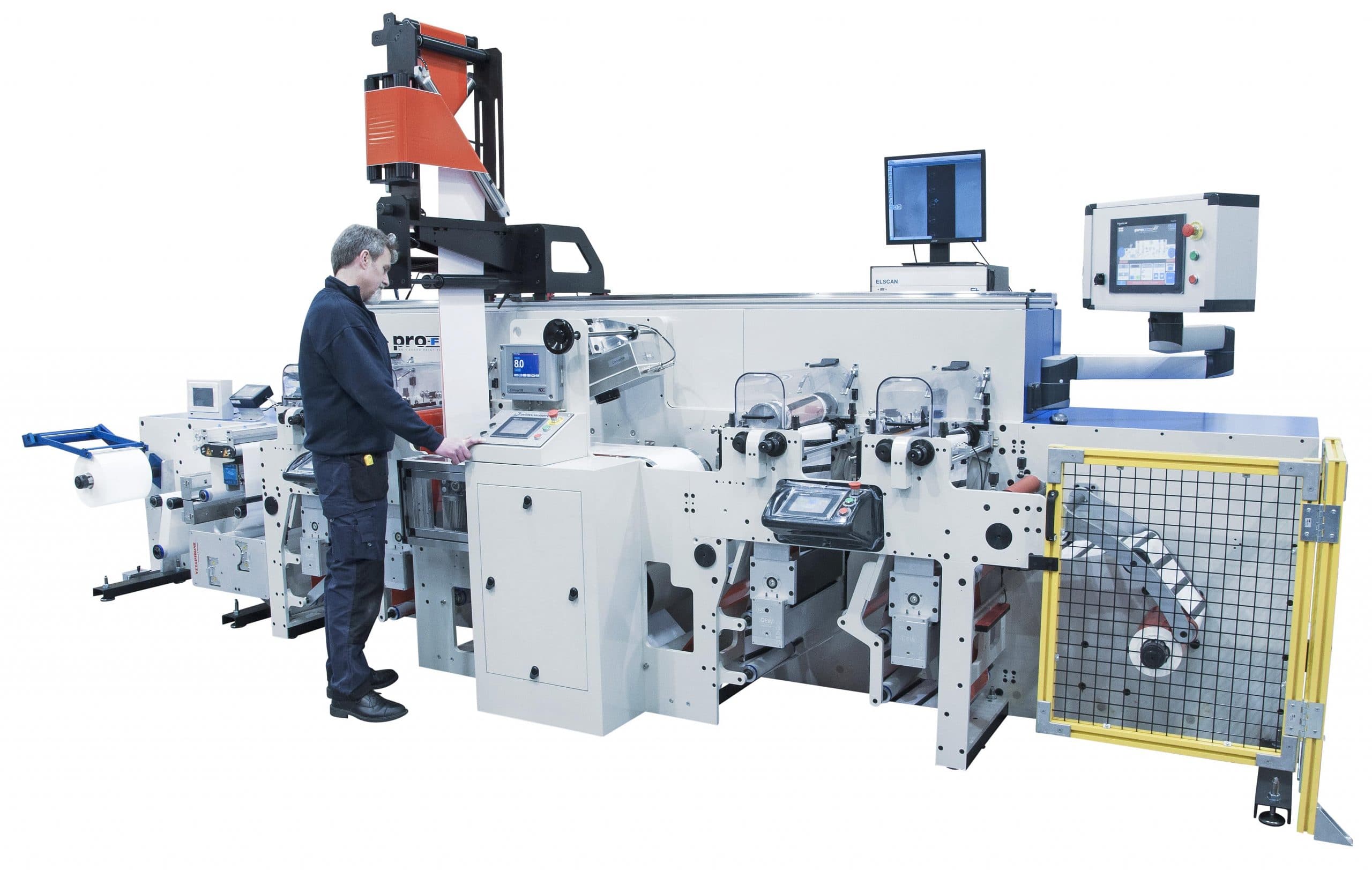

Narrow web flexo printing is a cost-effective and reliable solution for mid-large volume print runs. Operating with webs that, typically, are between 10” and 16” wide, narrow web flexo printing works well with UV-curable inks which dry quickly, thereby eliminating the need for additional drying equipment, and delivering a lower ink cost per square metre without compromising on image quality.

So, what sort of products can you print using narrow web flexo printing?

1) Labels and stickers

Self-adhesive labels are mostly produced on narrow web printing machines where several in-line processes can be combined to produce a multi-layer label or single-layer tracking label. Typically, narrow web presses for label applications are 250 to 430mm wide.

Flexo-printed labels can be produced to photographic quality and are used in many industries, including retail, commerce, chemicals, drinks production, pharmaceuticals, petrochemical, textiles, transport, steel, and agriculture.

2) Food packaging

Narrow web flexo printing is used to produce packaging, sachets and packet sleeves for the food industry, also Specialist products like Coffee cups on various substrates. With the web being less than 20” (500mm), this method is suitable for printing details, such as cooking instructions and ingredients, without blurring or smudging, including flexible products (such as confectionery), on which it may be more difficult to print accurately. When combined with the correct Inks Narrow web flexo printing is also considered safe for packaging that will contain food products.

3) Tickets

Tickets play a prominent role in society and are used for an extensive range of purposes, including concerts and shows, special events, parking, and travel. However, tickets are rarely identical and present specific challenges that are not commonly associated with other printed products:

- Tickets usually feature unique identifying codes or numbers, so it’s vital that the print method used is versatile in mass production.

- On smaller tickets, the printed information must be legible, even if a compact font is used.

If both sides of the ticket are printed, important details must not smudge as this could invalidate the ticket and prevent its use. - Some tickets require information to be printed at the Point of Sale, for example, an entry time to an event or exhibition. Special reactive thermal coatings are needed in this situation.

Narrow web flexo printing is ideal for ticket production as it retains the flexibility to adjust the information on each item without compromising on cost or efficiency.

4) Cartons

Increasingly, lightweight cartons – up to 300gsm+ – are produced using narrow web flexo printing presses, with which they can be printed, creased, and cut to form completed cartons in a single pass.

Typically, these cartons are small pharmaceutical boxes for tablets or tubes, on which very fine text is required to provide key user information and ingredients for users.

Contact us to find out more

To enquire about our narrow web flexo printing presses for your business, please call Focus Label today on 01949 836223.