Over time, printing machines in high-speed, high-volume production lines accumulate dirt and other contaminants, which can affect the quality of their output and cause mechanical failure. Cleaning the machines can, understandably, seem onerous, especially if you feel that valuable production time is being wasted while the task is carried out: after all, surely it’s more profitable to have your production line operating at its maximum capacity?

The truth is that failing to clean your printing presses thoroughly or regularly enough can store up more time-consuming and costly maintenance and repair problems for the future. Print quality may suffer too, leading to more reworks and a higher volume of waste.

How should Anilox Rolls be cleaned?

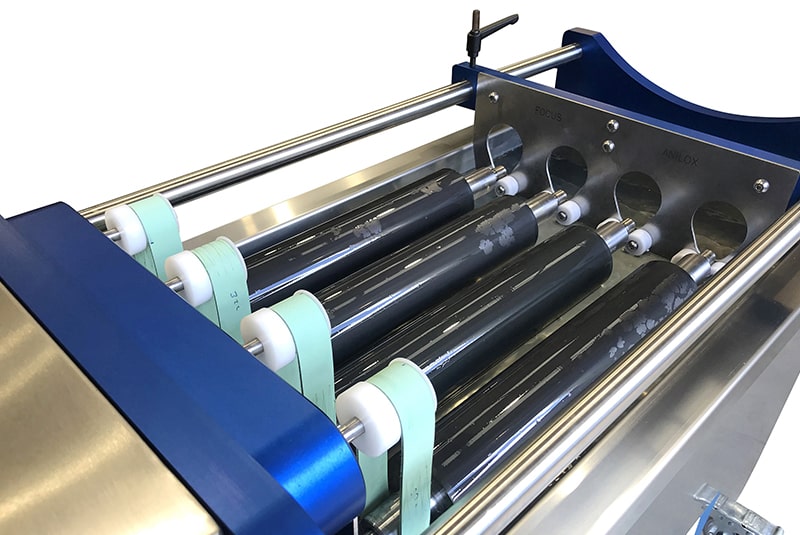

The Anilox roll is a key component in the printing process, but its performance will deteriorate over time. The cell structures of the roll may become blocked by dry ink, reducing the volume of ink that they can carry, and resulting in reduced quality, ghosting shadows & performance.

Cleaning with an ultrasonic Anilox roll cleaning machine is the most effective way to solve this problem and optimise your printing press’s performance. Ultrasonic cleaning will maintain the Anilox rolls in their original condition, saving your business money in the long run in these three ways:

1. Speed and efficiency

The cleaning process applied by the ultrasonic Anilox roll cleaning machine is short and gentle, taking only 30 minutes to complete. Ultrasonic waves are used to break up hardened ink in the roller cells and are so effective that all residues will be thoroughly removed before your printing presses are restarted. Because of the speed and efficiency of the cleaning system, you won’t need to shut down your printing presses for long periods.

2. No harsh chemicals

As the ultrasonic Anilox roll cleaning machine system uses only 95 per cent water and 5 per cent sodium hydroxide, instead of harsh chemicals, the rolls will be protected from damage during cleaning. Once the cleaning process is complete, the Anilox rolls will deliver the same exceptional performance as if they were brand new, saving you the cost of having to replace them.

3. Quick and easy to install

At Focus Label, we offer professional training and maintenance to support you with the installation of the ultrasonic Anilox roll cleaning machine. It’s a quick and easy process, eliminating the need for lengthy periods of equipment downtime but, should you encounter any difficulties, our expert team are on hand to help with any queries.

Contact us to find out more

For more information about the ultrasonic Anilox roll cleaning machine, please call Focus Label on 01949 836223 or send us a message and one of our sales team will contact you soon.