Increasing the speed of a printing press is a common goal for many printing businesses. After all, the difference between 300 fpm and 600 fpm, when evaluated over the course of a whole year, can make an enormous difference to the number of items that are printed and, consequentially to your profits.

ITMA 2019: What We Learned

The four-yearly ITMA textile and garment technology expo is the world’s leading event for the international textile industry, showcasing the latest in materials technology and technical innovation – including in textile printing. As such, it is a great opportunity for businesses like us to engage with suppliers, customers and friends in one place – and also to keep up to date with the changes transforming the industry.

What You Can Expect from Focus Label At Labelexpo 2019

Coming up at the end of next month is one of the highlights of our year for exhibitions: Labelexpo Europe 2019. We are delighted to be taking part as exhibitors and really look forward to meeting established customers and building links with new contacts in the industry. This article explains a bit about what we are up to and what you can expect from Focus Label Machinery at Labelexpo.

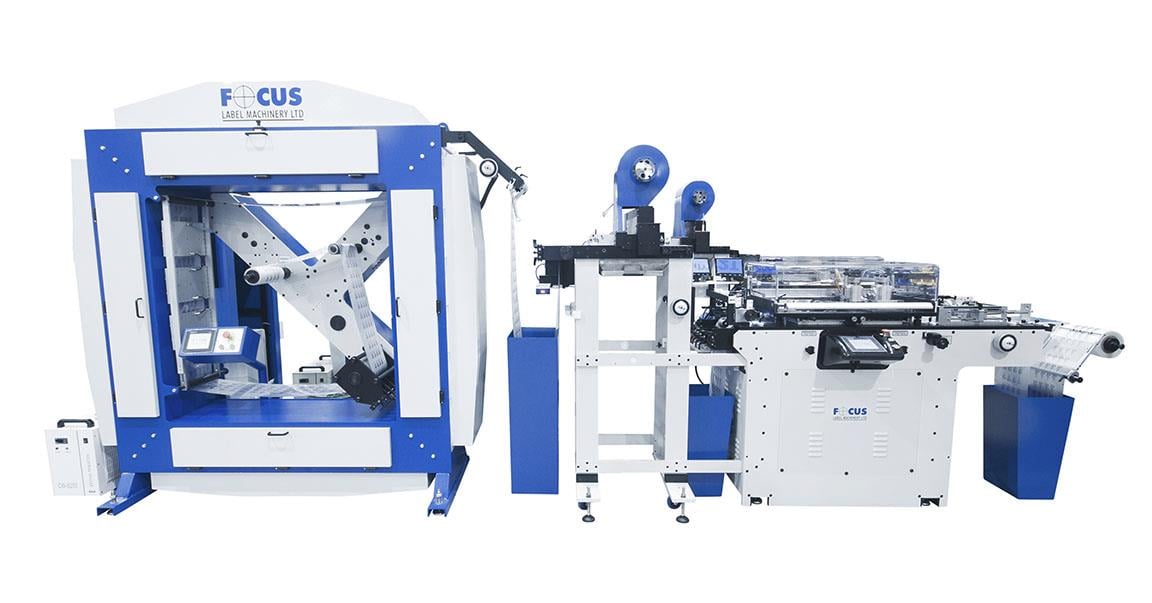

Flexo Press Installation At Advanced Labels

Focus Label Machinery have completed their latest installation at Advance Labels, Syston, Leicestershire. The family run company, established in 1993, have increased their capabilities with an 8-color, full UV Proflex 330SE servo-driven flexo press.

What Is Serigraphy?

Image: Tagtrans 225 Serigraphy is the artists' term for silk screen printing, a process which involves a stencil and ink which is forced through a silk screen, although modern versions are often made of nylon or finely woven polyester. One colour is applied at a time and a blade is used to sweep the ink smoothly across the press. Serigraphy is an extremely ancient form of printing and has been used since the days of the Chinese Song Dynasty (960 - 1279 CE) to transfer exquisite designs to silk material. In modern times, machine-based heat transfer silkscreen printing is used in the textile industry to mass produce attractive prints on fabrics, including t-shirts, curtains, cushion covers and bed linen. Heat transfer is also a popular alternative to sew-in garment labels, especially for underwear and swimming costumes.

ITMA 2019: Thanks For Your Support!

Three weeks home from ITMA 2019 in Barcelona and we are still reeling from what turned out to be an incredibly positive and exciting event. Exhibiting at a high profile international event such as this takes plenty of preplanning and hard work – but it was more than worth it for how well attended and well received our exhibition was this year.

.jpg)