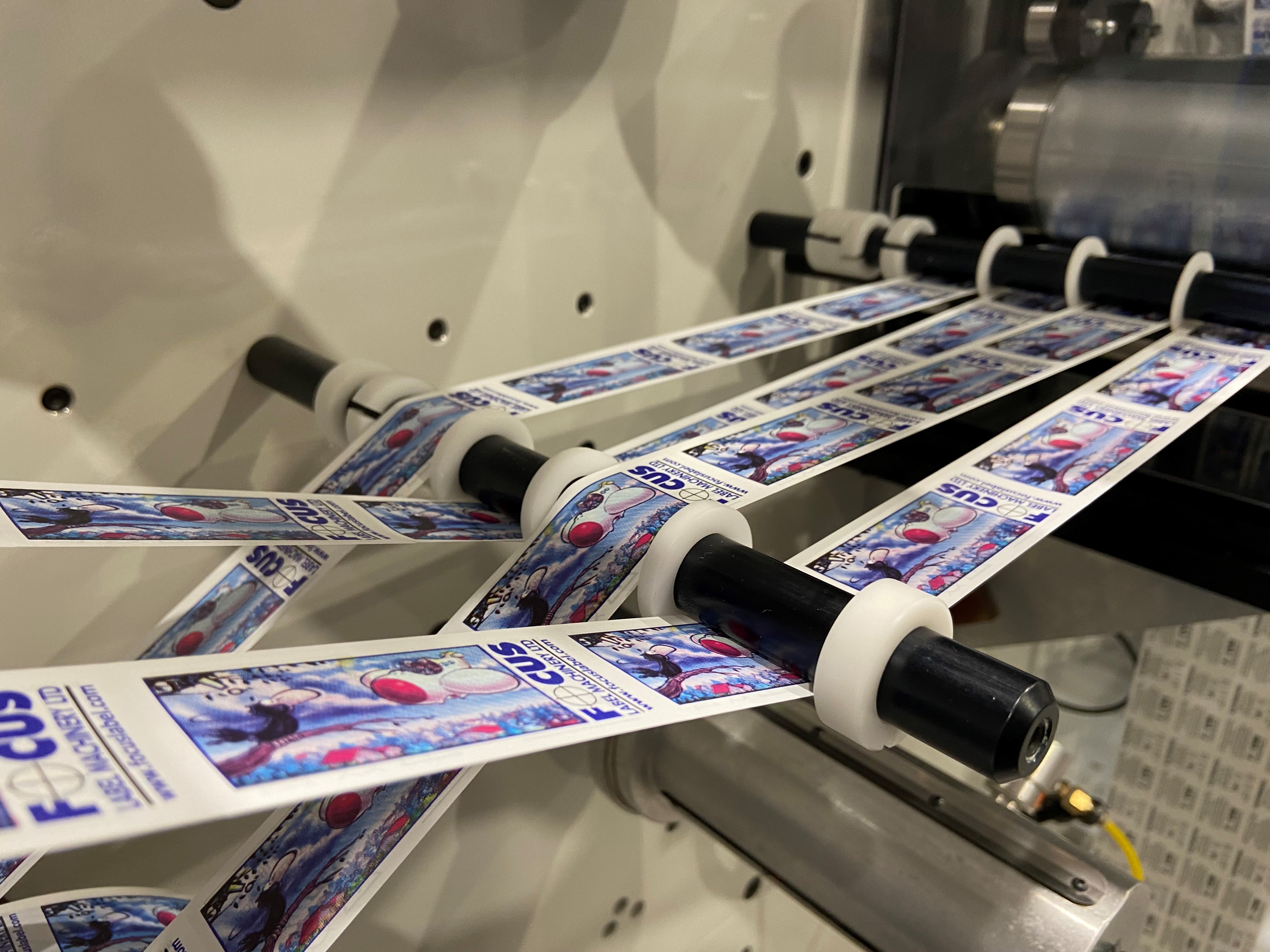

Narrow web flexo printing is a cost-effective and reliable solution for mid-large volume print runs. Operating with webs that, typically, are between 10” and 16” wide, narrow web flexo printing works well with UV-curable inks which dry quickly, thereby eliminating the need for additional drying equipment, and delivering a lower ink cost per square metre without compromising on image quality.

4 Of The Most Popular Products To Print With A Narrow Web Flexo Printing System

PRINTED GARMENT LABEL PRODUCTION ALIVE & WELL IN EUROPE

We are pleased to announce that Swedish Company Rudholm Group has just added another brand-new Focus LX printing press to its print facility which produces labels for the retail and garments sectors.

How To Maximise The Efficiency Of Your Textile Printing Machinery In Four Easy Steps

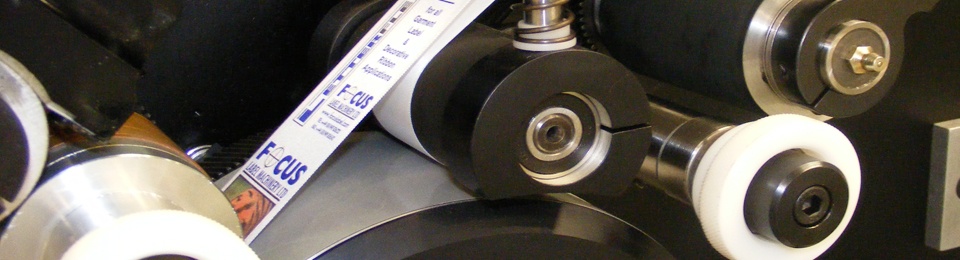

Any kind of textile processing, including the production of garment labels, relies on the continued efficiency of printing machinery. Without it, the quality of your textile printing will be inconsistent. There are many ways to maximise your machine’s efficiency. 1) Manage Humidity and Static Regardless of the type of textiles you print at your facility, humidity will play a role. Too-high humidity will negatively affect your machinery, causing damage and slowdowns in production. Adding to this, any change in the moisture content in the air can impact the textiles themselves. For example, added humidity will lessen the elasticity and tensile strength of some fabrics.

The Future of Textile, Label and Ribbon Printing

A crystal ball would certainly be a must-have item for anyone wishing to predict the printing trends of the future, as well as the costs to obtain them. This ever-changing industry is notoriously difficult to make predictions about. However, there are some occurrences which certainly do signal change in the textile, label and ribbon printing industries, and the news is very good.