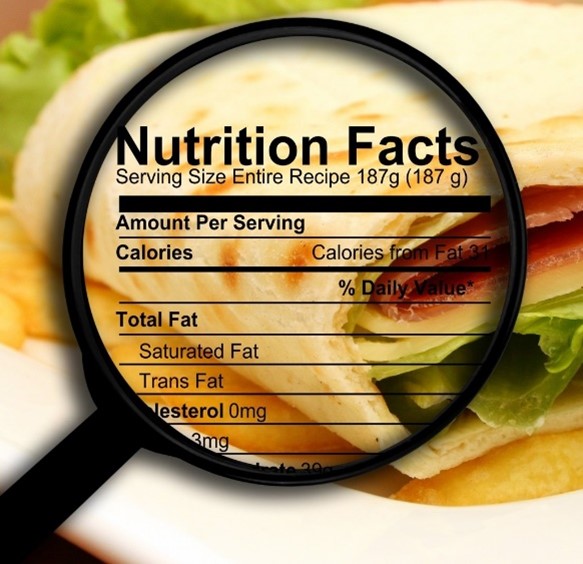

Changing regulations in the food industry mean it’s as important as ever that packaging and labels are clearly printed, so that consumers are fully informed about the nutritional content of their chosen products. But high-quality, professional label printing is also essential to attract consumer attention and improve the saleability of food items, particularly on the crowded supermarket shelves where multiple brands are displayed. Clients need their brand to stand out.

The use of UV-LED inks is one of the fastest growing areas of the print industry for a variety of general applications, including posters, catalogues, and flyers. UV-LED printing inks for food packaging is still relatively new but growing in popularity, so what are the benefits of switching to this form printing Inks for Flexographic & Digital machinery?

1) Fully Compliant With Food Safety

In all aspects of food manufacture and production, it is vital that consumer safety is guaranteed. Standard UV inks do need meet migration & safety requirements for direct packaging. Low migration LED-UV inks are designed to minimise the passage of ink compounds into foods and are, therefore, suited to usage in many prime food packaging applications.

2) Unrivalled Versatility

The high degree of curing is a key element in the use of LED-UV inks, particularly to produce a range of food-safe packaging that doesn’t require the use of a separate label. LED-UV ink prices are more competitive, as print can be applied directly to packaging materials, such as food tubs, cylindrical or conical cups, and PET bottles.

3) An Effective Way To Cut Costs

Overall, LED-UV inks have a short set-up time and low rate of waste: when used with flexographic or digital printing technology, they enable a very precise print run length to be defined, thereby reducing waste, and giving a more predictable idea of cost. LED-UV equipped printing presses are cheaper to operate and maintain, with lower energy costs, fewer moving parts that require regular service and a longer lamp lifespan. The return on investment (ROI), therefore, is higher and quicker than with other forms of printing.

4) Reliability

Flexo & Inkjet printing applications are often chosen for their reputation for reliability and speed. The use of LED-UV Inks in food packaging printing reinforces this notion, as it delivers the most reliable low & high volume printing process, even when operated at high speed. In print applications where speed is of the essence, LED-UV inks are particularly suited to flexographic machines, which deliver premium quality output for food labels that radiate luxury and quality.

5) An Environmentally Friendly Solution

The UV-LED drying process is much more environmentally friendly than alternative drying methods, with lower power demand during curing, no ozone emissions, and 20 per cent lower ink consumption. Not only will energy bills be lower, but your business’s carbon footprint will also be reduced, so you can authentically market your brand as eco-friendly.

Contact Focus Label To Find Out More

At Focus Label, we design & supply LED-UV Presses for businesses seeking to make a dramatic impact in their carbon footprint & running costs while maintaining high-quality and eye-catching print for food packaging & labelling that doesn’t burn a hole in their finances.

To find out more, please download our free Conventional UV vs LED Printing Guide today or call us on 01949 836223 for advice.