There are times in life when small differences mean a world of benefits. A tweak here, a thoughtful addition there, or a bit of extra investment. In the world of flexographic printing the result can be increases in productivity, energy efficiency, and quality.

Enter Proflex, our most thoughtful, high quality, effortless series of printing presses. Advance warning: there are some boasts coming up. However, they are forgivable, as Proflex is the result of years of hard work, investment, and creative development. Read on to find out more.

Proflex: A Brief Biography

Proflex presses are a modern response to the demands facing the printers of today. This is an era where flexibility and efficiency are everything. It’s no small ask when it comes to the printing press, traditionally the preserve of complex and unwieldy machines that are meticulously fond of their uninterrupted routine.

Proflex is different.

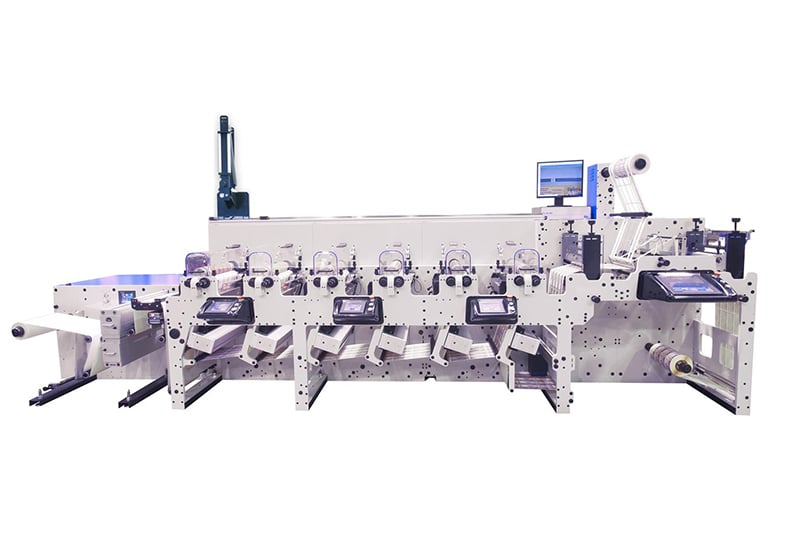

Tailored to all volumes with high productivity, Proflex machines combine open architecture print platforms with state-of-the-art Servo technology and touch-screen operator interface for complete control and ease of use.

This means that functions such as rewind and unwind can be achieved with the brush of a finger, whilst information can be stored, recalled, and analysed within moments. Tension control and other variables can be pre-programmed to guarantee accuracy.

All of this is achieved in combination with one of the greatest assets of the Proflex series: its silence. Many subtle measures have been taken to reduce both noise and vibration. This not only reduces cumulative wear and tear on the machine, but also improves accuracy and print quality for the sharpest image.

Taking Control, Embracing Choice

Today’s organisations need to be adaptable, forward-thinking, and primed to stride into new opportunities with confidence. Knowing what’s around the corner can be a challenge, so Proflex is a solution with a philosophy of choice and control.

There is a choice of drying systems, such as IR, LED, and UV, or a combination of all. Cold or hot foil is available. For finishing, Air Cores can be supplied in a variety of sizes. A rail system means that a wide variety of different options can be mounted, moved, and – thanks to the lack of vibration – guaranteed to stay in place.

Taking that choice in ever more exciting directions, Focus can also build machines that incorporate Packz software. All of these flexible features compliment a solid, reliable, high-quality machine with the latest tech and highest guarantees.

Quality & Reliability

If you need a reliable, quality, and efficient solution for labels, tickets, and cartons, look no further. The advanced range of choices on our Proflex machines - available as a mechanical version, Proflex E and a Servo version; Proflex SE, meaning you can tailor them to your individual needs. Whether it’s energy saving UV drying systems, easily accessible parts, or the ease of world-leading digital interface, Proflex presses have a solution for every need.

If you’d like to learn more about how these machines can boost productivity and efficiency, you can book a visit to our Nottingham showroom. Seeing the machines in action is a great way to get the gist of what they are capable of, and we are always interested to listen to your needs.

In the meantime, click here to view latest Proflex range online.