Once every four years the textile machinery industry comes together for a mammoth exhibition. Preparations are well underway for this year’s international trade show for Textiles & Garment production. ITMA is the trendsetting textile and garment technology platform where the industry converges every four years to explore fresh ideas, effective solutions and collaborative partnerships for business growth. Organised by ITMA Services, the upcoming ITMA will be held from 20 to 26 June 2019 in Barcelona at Fira De Barcelona, Gran Via.

Invitation To Visit Focus Label Machinery & Our Manufacturing, Production & Showroom Facilities

March 26th & 27th 2019 Focus Label Machinery Ltd Bingham Nottingham: Focus Label Machinery alongside partners Phoseon Technology & Industrial Inkjet, will be showcasing UV LED Flexo and Digital Inkjet solutions, presenting the latest in drying systems and the high resolution KM1800i inkjet heads at our showroom in Bingham - close to Nottingham.

An Exciting Opportunity Has Opened For A ‘Business Development And Marketing Manager'

Job Purpose: Consultative business approach to understand the requirements of today’s Label Print business. UK and International Sales. Develop new channels to market. Building strong relationships with existing partners/OEM companies and engaging with potential new partners/OEM companies to work with Focus. Build strong UK an international company brand.

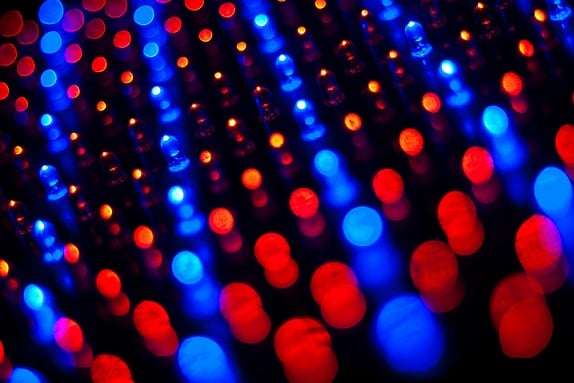

LED Drying Tech: The Future of Flexography

Here at Focus, we’re absolutely dedicated to innovation. It’s one of the reasons that we’re sponsors of the 2018 Flexo Tech Innovations Awards, and is also one of the reasons that we pursue partnerships with some of the most dynamic tech firms in the world. In one of our most exciting recent developments, we’ve teamed up with Phoseon, a US-based UV LED manufacturing company. The result has revolutionised flexography. Here’s an introduction to the future.

Our Narrow Web Rotary Flexo Printing Machines: Reasons To Invest In 2019

We live in a landscape augmented with transposed colour. Whether for labels, or fabrics, or posters, or logos, printing has become a central communication enabler in our society. As such, more companies than ever before are learning that continuous printing is not only useful, but central to their needs. And the competition is tightening.

The Softly-Softly Approach Brings Family Together

Check out this article from our good customer Last Bros Ltd. A very interesting development for them - merging and investing for their future.