On several levels digital printing cannot be compared directly with conventional printing systems. In fact each of the systems discussed can have a defined appearance compared to analogue printing. This is no different to comparing the subtle differences in gravure, flexographic & lithographic printing. The digital option will have different rules relating to costs & price pressures and anyone expecting this new technology to replace their existing analogue equipment with a simple press of a button will be disappointed. Digital printing requires a lot of advance preparation in the presented files, the saying rubbish in, rubbish out is absolutely true in this case. In asking the right questions & preparing trials you can manage expectations and make the right choice for your market.

On several levels digital printing cannot be compared directly with conventional printing systems. In fact each of the systems discussed can have a defined appearance compared to analogue printing. This is no different to comparing the subtle differences in gravure, flexographic & lithographic printing. The digital option will have different rules relating to costs & price pressures and anyone expecting this new technology to replace their existing analogue equipment with a simple press of a button will be disappointed. Digital printing requires a lot of advance preparation in the presented files, the saying rubbish in, rubbish out is absolutely true in this case. In asking the right questions & preparing trials you can manage expectations and make the right choice for your market.

1) Provide a number of test jobs which is typical of the type of work & application you intend to use the digital system.

2) Test the same job on a selection of substrates for print quality comparison.

3) Check ink usage & cost (bear in mind ink costs are much higher than analogue printing).

4) Confirm if substrates are specially coated & confirm costs.

5) Hidden charges. Are there any click charges (some systems make a charge per print), or service charges.

6) Are there any monthly service & maintenance charges.

7) Do you need to purchase any additional software packages, computer hardware.

8) The future. Is the system about to be superseded by a new model.

9) Ask the right questions, listen carefully & read between the lines.

What Should a Digital System Provide?

- Instant press proofs close to a clients approved print runs.

- Instant costing for ink & substrates.

- Reduced repro costs.

- Fast turnaround times.

- Production of small & medium press runs to meet each customer’s needs, helping them manage their inventory more effectively.

- Variable Data Print, sequential numbers, numerous barcodes and full colour product personalization of each printed image.

- A variety of printable substrates.

- A cost effective print & finishing solution.

- Reliability

Today’s Leading Label Printers Are Integrating Digital Into Their Flexo-Based Label Printing Businesses

Whether it’s a digital UV inkjet printer mounted onto their flexo press for printing variable data, a stand-alone digital press that serves as operational relief to their flexo, or a flexo-digital hybrid label press, label printers are realizing the benefits that digital technology brings.

Why is Digital a Complementary Technology to Flexo?

Digital can add value to your end product without adding to the process or costs of production, indeed by combining flexo & digital you can take out additional processing costs.

What Are The Drivers & Trends For Adding Digital Printing?

Small runs, personalisation, variable data, reduced inventory, response & reduced lead times, initial proofing

Who is Adding Digital Printing to Their Business?

Most businesses are considering digital in some form for their commercial applications, fortunately there are various entry price points to consider for equipment solutions.

When is The Best Time to Add Digital Printing?

Anytime now is a good time to start, with the ever changing technology landscape, waiting for tomorrows latest advance never comes.

How Can I Make & Save Money by Adding Digital Printing?

You can reduce reprographics & plate costs by switching to digital, combine processes to remove an operation. Some companies offer a print service to other printers, becoming a Trade print hub for local companies.

Where Can I go to Learn More?

Start on the internet, visit trade shows, and carry out trials with systems manufacturers and talk to suppliers.

How Many Colours

Typical systems offer Mono or a minimum of 4 process colours. A combination of these process colours can produce a wide range of colours & effects. But the colour gamut range is limited and to some degree colours are transparent thus affected by the substrate colour. In order to achieve specific pantone colours outside the normal gamut some manufactures provide 7 or 8 colours to increase the colour range and allow adjustment according to substrate colour, other manufacturers offer a separate white head to provide a substrate block or base to apply CMYK. A hybrid system Digital /Flexo can provide a 100% colour gamut

Colour Management Software

Taking your image file and turning it into a high quality print the most vital part of your new print engine. Most systems come with a standard colour management software package, these can be very basic or difficult to navigate, at worse not provide the best results on your system. More intuitive add on packages focused on labels may prove worth consideration. Suites of modules packages can be tailored to your application, but can be expensive and often require an annual fee for a user licence. The advantage is you will always have the latest user friendly version, and the latest advances in digital print processing to optimise output & production.

Work Flow Software

Software to plan workflow & production has been available for many years, but has progressed to include digital & combined hybrid processes. Managing job workflow to optimise production schedules is key to getting the best out of your conventional & digital print production. The ability to group jobs according to printing method, material choice, colours, tooling will improve efficiency, productivity & profit margins. New jobs can optimised at the start of reprographics stage, screening for a particular press or system, eliminating the need to make unregulated changes in the print shop & in turn reducing duplication & waste.

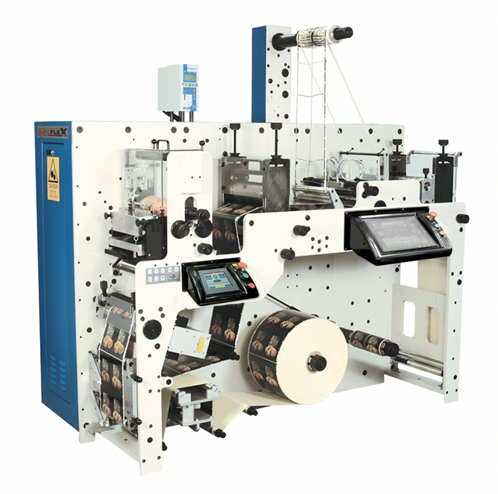

Off Line Finishing

Separate finishing equipment has been available for the past 20 years, using servo technology in semi & full rotary equipment to provide good register between pre-printed substrates & the desired cutting lines. Flexible Cutting Dies are the tool of choice to minimise cost and are easy to change forms with the minimum of disruption. Optional finishing systems like embossing, hot foil, cold foil, over varnishing & spot varnishing are readily available.