Have you ever wondered whether investing in a new flexographic press is worth it? Currently businesses need to choose their investments wisely. This is particularly the case for flexographic Printing Presses. Designed to last for decades, flexographic presses quickly become a crucial element of the fabric of the organisation. It pays to get it right. Here are some of the reasons why the right modern flexographic press can enhance your company.

Increased Productivity

There are many reasons that productivity can suffer without the right tech or even old outdated equipment. Outsourcing can lead to inefficiencies, supply chain problems, and a lack of organisational flexibility. With a modern flexographic press, there are no delays or uncertainties. You have the control to complete orders reliably and on schedule.f

Increased Profits

Whether it’s to keep investors happy, to expand, or simply to ensure long-term security, profits are vital. Modern in-house printing presses can boost profits in many ways. Today’s flexographic machines are fast, efficient, and easy to use. This means rapid run rates & reduced set up times, with low risk of error, and less need for highly trained staff. Because of this, you get the results that you want quickly and reliably, keeping costs low and freeing up valuable working hours maximising available production time.

Digital Precision

Today, everything is turning digital…! Well the fact is Digital printing accounts for less than 10% of commercially printed products, a small percentage of packaging applications. Digital print is more than often not competitive when compared to most analogue printing systems, however there are some applications where digital wins out such as variable data & low volume promotional print. The latest flexographic presses do pack in a lot of Digital technology, from Servo drives, digital tension systems to storage and transfer of production data. A modern Flexo press is a marvel of the analogue printing world with its ability to print economically across a wide range of print & packaging applications.

Looking at the wider aspects , digital technology has brought a host of benefits to the flexographic stage which enhance its productivity, quality and long term future at the sharp end of print & packaging. Reprographics, artwork, workflow, production planning, costing, invoicing are all making a positive influence on the printing industry and production cycle.

We work with Packz, which was created by world-leading graphic designers and engineers, and – as a result - has one of the most varied ranges of capabilities. If you want to have control of every phase of the packaging, Packz is a visual masterpiece and can be used with a mixture of analogue & digital print technologies.

Looking forward the ability to integrate a digital print engine into a conventional Flexo press is a reality, importantly is takes the best of both technologies to offer a level of service not possible before. Digital means that at the click of a button, one person can effortlessly command an accurate, high-quality, rapid print run.

Flexibility

In the competitive business arena, flexibility is an important asset. Whether it’s trying new product lines, expanding the brand experience, or racing to fill a tempting market opportunity, success is about having the flexibility to move quickly. Those investing in the latest equipment & business systems will be best placed to take advantage of the opportunities.

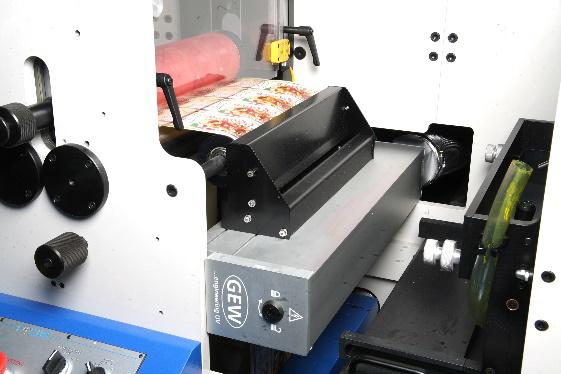

Today’s flexographic technology has been designed with sleek efficiency in mind. From high levels of control over varied print runs, UV drying technology that takes a machine from idle to operational in seconds, to the ability to print on a dazzling array of substrates, flexographic machines are a powerful ally in the organisational arena.

Eco-Considerate

Businesses are increasingly being asked to account for their carbon footprint. One of the reasons that Focus continues to invest in the development of new flexographic machines is to target core issues such as energy consumption. Today’s Flexo presses occupy the capacity of two or three traditional presses, dramatically reducing energy consumption whilst simultaneously increasing output.

Energy-saving features include UV & LED UV drying technology and automatic air recirculation. Combined with the naturally ecologically friendly potential for flexographic machines to use non-toxic ink, the result is a powerful piece of kit with a surprisingly gentle nature.

Meet Your Business Goals With A New Flexo-Press

Whether the goal is increasing productivity, reducing costs, or increasing options, if you’re keen to explore the ways that a new flexographic can benefit your organisation in 2019 then please get in touch!

We offer guided tours of our showroom, where you can see the latest flexographic & digital presses in action. There, we can answer any questions, and help with detailed costings and timings so that you can make a detailed assessment of the benefits that a new flexographic press can offer. We’re also always here on the end of a good, old-fashioned phone. Our number is 01949 836223.