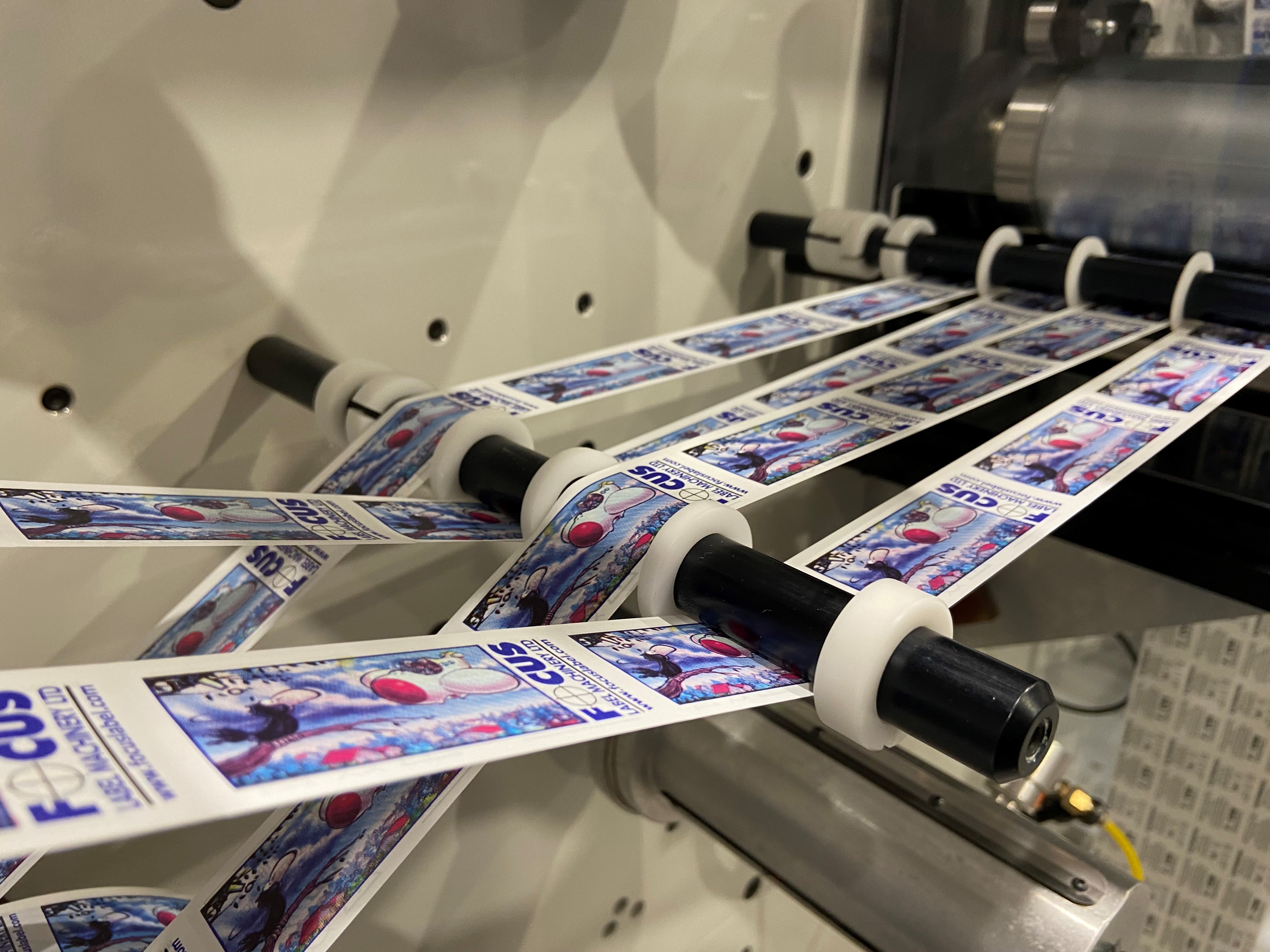

We are pleased to announce that Swedish Company Rudholm Group has just added another brand-new Focus LX printing press to its print facility which produces labels for the retail and garments sectors.

PRINTED GARMENT LABEL PRODUCTION ALIVE & WELL IN EUROPE

How To Reduce Your Printing Press Lifetime Repair Bill

During the pandemic, manufacturers of equipment have been under pressure to reduce stock levels of parts & spares for their older equipment, often leaving end users with reduced levels of support. Some manufacturers have taken the decision that they will no longer provide service or parts for equipment long since out of production. Some specialist parts such as electrical control boards can no longer be found or are uneconomic to repair.

Arc Labels Installs Konica Minolta AccurioLabel 230 From Focus Label Machinery

Yorkshire based label printer, Arc Labels has installed an AccurioLabel 230 digital toner press, manufactured by Konica Minolta and sold through Focus Label Machinery Ltd. The new press will complement existing Focus flexo presses and Newfoil hot foil presses in order to enable the company to provide a broader range of labels, from low volumes to high volumes – across a wide range of market sectors and applications.

Post-Covid Recovery 2022 – Why You Should Invest In Digital Printing & Finishing Systems

The Covid-19 pandemic has been a disruptive force for supply chains the world over and has compounded many issues that were simmering below the surface. The weaknesses of the predominant supply chain models before the pandemic – notably ‘just in time’ and ‘lean manufacturing’ – which depended on extended supply chains, tight delivery windows, and minimal stock holdings, were laid bare by worldwide parts and labour shortages, and spiralling transport costs.

Case Study – Double Reflex 250/350 Implementation for Labfax

The pandemic revealed a pressing need for greater scalability and flexibility among many UK label printing businesses. Fortunately, the digital printing and finishing technology already exists to allow businesses to scale production to changing market needs while keeping production costs low, and to facilitate rapid growth when required.

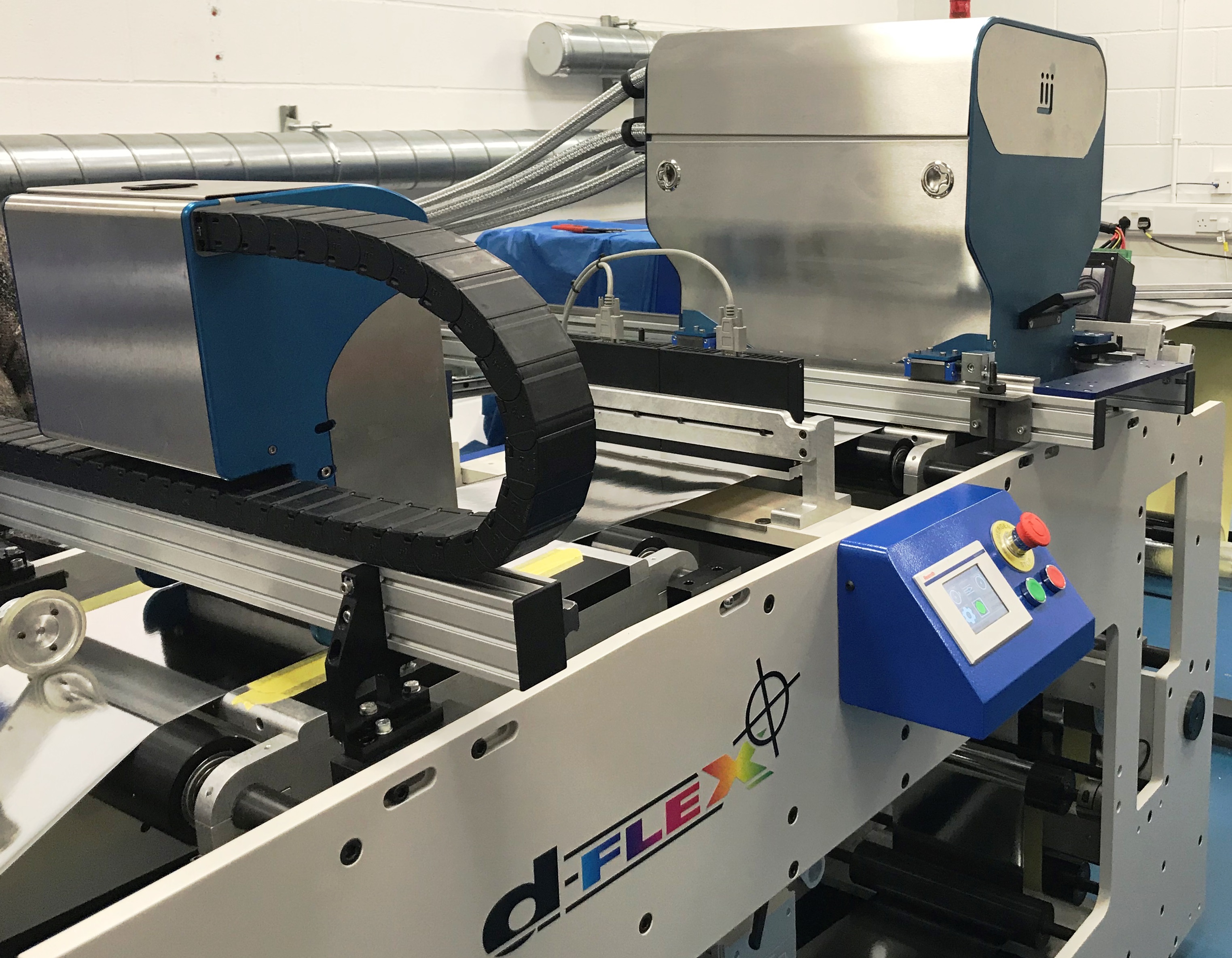

TOPS modernises machine park with Focus label eFlex

TOPS spol. s ro has developed from a trading company to a manufacturer of self-adhesive labels in the Slovak Republic since 1991. Mainly forgery-proof security labels are produced, but multi-colored labels on a wide variety of materials as well as thermal transferlabels are also part of the portfolio. That made the investment in a new machine necessary.