The pandemic revealed a pressing need for greater scalability and flexibility among many UK label printing businesses. Fortunately, the digital printing and finishing technology already exists to allow businesses to scale production to changing market needs while keeping production costs low, and to facilitate rapid growth when required.

We recently carried out the implementation of two new customised Focus Label Reflex 250/350 digital finishing systems for Labfax, a label printing business based in Telford. The case study below is an illustration of the ways in which our machinery can help businesses overcome a range of challenges and reach business objectives, and we are grateful to Labfax for the opportunity to share this information on our blog. If you’d like more information, please don’t hesitate to get in touch.

The Goal

Like many businesses in the label printing industry, Labfax had a mixed suite of analogue & digital printing presses and finishing equipment that met the needs of the business at the time . However, as the business grew in the years leading up to the pandemic, and then demand for smaller volume orders rapidly increased after the end of lockdown in summer 2021, the static nature of their equipment became less able to cope with the demands of their customers.

An investment was therefore needed that could scale with Labfax’s growth objectives over the coming few years, could provide a responsive service to customers, and was resilient enough to provide a backup should market conditions change.

Labfax were already an established customer that had purchased two regular finishing systems from us in the past, so we met with their Operations Director, Claire Radnor, to discuss how we might be able to help facilitate their growth plans.

The objectives that came out of our meeting were:

- To modernise their range of label production equipment (as part of an ongoing modernisation and streamlining strategy throughout the business)

- To increase their overall production capacity and lower turnaround time

- To improve print quality across a broader range of substrates

- To implement a versatile platform with scope dual purpose and facility for technology upgrades

- To acquire a modular system that can scale in response to future business needs.

How We Helped

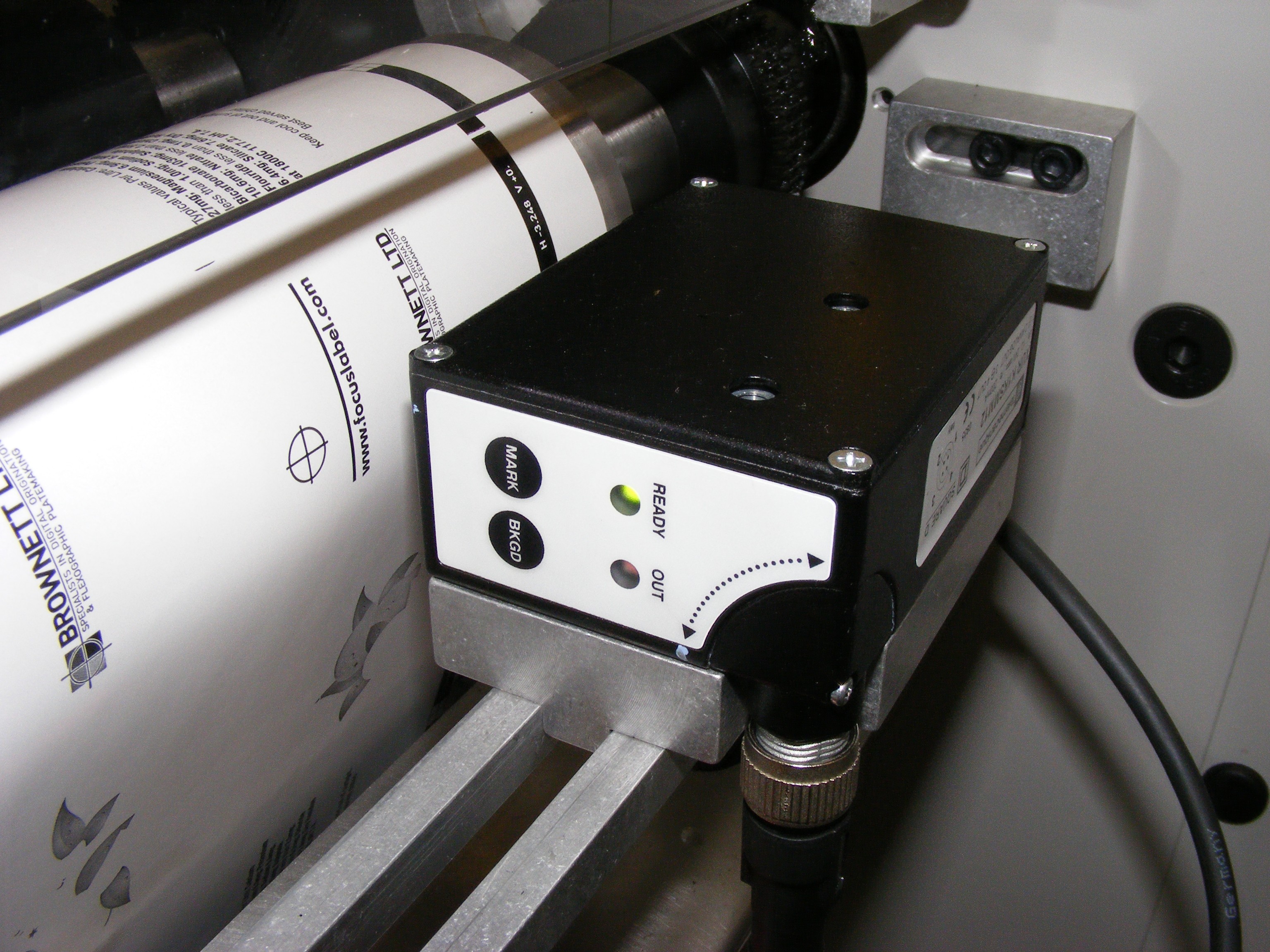

To enable Labfax to reach these goals, we recommended two new Reflex 250/350 finishing systems. Our Reflex 250/350 model is a servo finishing system for digitally pre-printed webs, with an accurate re-registration facility that enables the high speed finishing of digitally printed labels. The units ordered by Labfax came with several additional features, including:

- Single colour print module with quick change print cassette system – this enables print cassettes to be removed and changed in seconds, enabling fast job changeovers and easy clean-up.

- Spot colours

- Over varnish

- Laminating

- Die-cutting

- Slitting

- Rewinding equipment

The equipment came with two interchangeable drying modules: LED UV or IR

1) Infrared (IR) drying system – this ultra-efficient drying system is combined with a forced cold air flow, for Water based Inks allowing quicker curing speeds without heat build-up.

2) LED ultraviolet (UV) drying system – the supplementary UV drying module can be used for high-speed varnishing , flood coating & Spot Colours.

We also recommended several performance-enhancing accessories for the Reflex units, which included:

- Cold foil

- Turn bar

- Delam-relam

- Digital inkjet print engine, with semi or fully rotary converting options

Outcome

The Labfax team were happy with the choice of equipment, and we managed the delivery, implementation, and training schedule for the units to fit in with their production schedule, with minimal disruption to their business.

Claire Radnor commented:

“As our business has continued to grow, we decided that new investment was required to modernise our production line. The modular nature of the Reflex provides a scaleable foundation to add new features at a time that suits our business. We already have a good partnership with Focus and had no hesitation in ordering the two new Reflex presses from them. The equipment is well made, reliable and the back-up support service is excellent. This latest installation makes a total of four finishing systems for Labfax in the last two years.”

About Labfax

Labfax provide custom label printing, finishing, and application services to UK manufacturers in the automotive supply, pharmaceuticals, and industrial chemicals sectors. They are also the official UK distributor of CAB label printers, print application, and marking systems, providing product supply, implementation support, and after sales care. Labfax’s recent specialist label printing projects include labelling for Covid 19 testing kits, car identification labels, labels for cryogenic containers, laser markable labels, and oil-resistant labels for vehicle supplies. More information about their products and services is available on the Labfax website. To find out more, please contact the Labfax sales team directly on sales@labfax.co.uk, and they will be happy to help you.

Summary

It was a pleasure working with the Labfax team on the implementation of their new Reflex finishing systems, and we look forward to an ongoing business relationship with the company in the coming years. At Focus Label, our service doesn’t stop after a sale has been made, but extends to bespoke installation, training, technical support, and ongoing maintenance/repairs. This enables our customers to reach the full operating potential of their printing equipment in less time and get more value from their investment – ultimately leading to a greater lifetime ROI and lower cost of ownership.

Next Steps!

To discuss your production requirements with one of our team and find out how our printing solutions can help improve productivity and efficiency in your business, please call 0115 824 5426 today.

Email: admin@focuslabel.com

Web Site : www.focuslabel.com