Drupa 2016 will see live demonstrations of the very latest models from Focus Label Machinery Ltd., with Servo & Digital solutions at the forefront, for the short & medium print run business.

The d-Flex digital inkjet press incorporates the latest high-speed full-colour Konica Minolta inkjet technology into the existing REFLEX servo press with in-line UV flexo print head, die-cutting, slitting and rewinding. Visitors will be able to see high quality variable images, overprinted in perfect register with UV flexo ink, then converted & rewound – in a single pass with speeds up to 50 metres per minute.

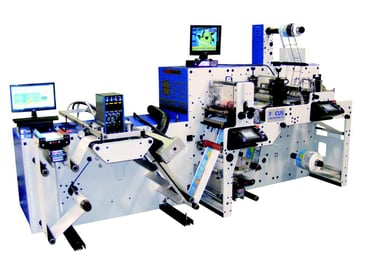

For pre-printed digital printed web, the REFLEX S SERVO converting system provides a comprehensive off-line finishing solution. Focus will demonstrate the accuracy of its re-register system - even at speeds of over 100 metres per minute. The full rotary system incorporates flexo printing/coating, cold-foil, laminating plus varnishing & die-cutting facilities in either roll to roll, or roll to sheet applications.

In addition, Focus will show the brand new e-FLEX model providing a new flexo/digital combination press platform for meeting the demand of medium & short run business. The TWIN-SERVO system provides single touch set ups, with minimal waste for conventional printing and can be combined with a digital module for variable data, text & images. The touch screen HMI operator controls, a fully programmable digital platform, plus storage of job details for future retrieval, all help to make the e-FLEX, the most effective, affordable servo-driven flexo / digital combination press in the marketplace today.

At the show, Focus will show a 6 colour, 330mm wide press, equipped with full UV drying.

The e-FLEX incorporates top loading print cylinders, Rapid-Change print cartridges to reduce downtime and set up times. A choice of ultra-efficient interstation drying systems enables much higher press speeds. The short web-path allows for a compact design, whilst still maintaining good accessibility for the operator and plenty of space for optional equipment. IR ,UV drying with chill-rolls is available, as well as delam/relam, rotary cold foil transfer, silk screen, turn-bar, sheet conveyor, enclosed/chambered ink cartridges, plus many other options.

Focus will also launch a new generation of the popular Proflex compact flexo press with open architecture print head design

The Proflex SE is a servo driven, modular press available with print widths of 250mm and 330mm. Several different drying systems are available, including full UV, LED, Infra-Red or combination drying systems, with optional chill rolls for heat sensitive substrates. The open architecture design of the print stations enables easy loading of ink cartridges and print cylinders, whilst interchangeable print cartridges can be partially or fully unloaded and exchanged, in order to maximise productivity and minimise downtime. Bearer rings are incorporated into the print cylinder assembly, to guarantee accurate print impression settings, regardless of substrate.

For more details of FOCUS equipment, visit: www.focuslabel.com or contact : admin@focuslabel.com